Business inventory management is a critical aspect of supply chain management that involves planning, organizing, and controlling the flow of goods within a business. Effective inventory management ensures that businesses have the right amount of inventory at the right time to meet customer demand while minimizing costs and maximizing profitability.

This comprehensive guide will delve into the various techniques, systems, and strategies for optimizing business inventory management, enabling businesses to streamline their operations, reduce waste, and enhance customer satisfaction.

Inventory Control Systems

Inventory control systems are crucial for businesses to effectively manage their inventory levels, ensuring they have the right amount of stock to meet customer demand without overstocking or understocking. These systems help businesses optimize their inventory management processes, reduce costs, and improve customer satisfaction.There are two main types of inventory control systems: perpetual and periodic.

Perpetual inventory systems continuously track inventory levels in real-time, while periodic inventory systems update inventory levels at specific intervals, typically at the end of a period or when a physical inventory count is performed.

Comparison of Perpetual and Periodic Inventory Systems

| Feature | Perpetual Inventory System | Periodic Inventory System |

|---|---|---|

| Inventory Tracking | Continuous, real-time tracking of inventory levels | Periodic updates, typically at the end of a period or when a physical inventory count is performed |

| Accuracy | Generally more accurate, as inventory levels are updated in real-time | Less accurate, as inventory levels are only updated periodically |

| Cost | Typically more expensive to implement and maintain | Less expensive to implement and maintain |

| Complexity | More complex to implement and manage | Less complex to implement and manage |

| Benefits | Provides real-time visibility into inventory levels, allowing for better inventory planning and control | Provides periodic updates on inventory levels, which can be useful for businesses with relatively stable inventory levels |

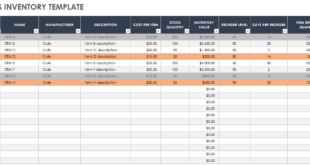

Key Features of a Computerized Inventory Control System

Computerized inventory control systems offer several key features that can help businesses improve their inventory management processes:

- Real-time inventory tracking

- Automated inventory replenishment

- Inventory optimization algorithms

- Integration with other business systems, such as accounting and sales

- Reporting and analytics capabilities

Flowchart of a Manual Inventory Control System

A manual inventory control system involves several steps to maintain accurate inventory records:

1. Physical inventory count

A physical count of the inventory is performed periodically, typically at the end of a period or when stock levels are low.

2. Recording inventory data

The inventory count data is recorded in a spreadsheet or inventory management software.

3. Calculating inventory value

The value of the inventory is calculated based on the unit cost of each item and the quantity on hand.

4. Updating inventory records

The inventory records are updated with the new inventory count and value.

5. Generating inventory reports

Inventory reports are generated to provide visibility into inventory levels, trends, and other relevant metrics.

RFID Technology in Inventory Management

Radio Frequency Identification (RFID) technology uses radio waves to identify and track inventory items. RFID tags are attached to inventory items, and RFID readers are used to read the tags and collect data about the items, such as their location, quantity, and other relevant information.RFID technology offers several benefits for inventory management:

- Improved inventory accuracy

- Reduced labor costs

- Enhanced inventory visibility

- Increased efficiency in inventory management processes

Inventory Valuation Methods

Inventory valuation methods are crucial for businesses to determine the value of their inventory and ensure accurate financial reporting. Different methods are used depending on the nature of the inventory and the specific requirements of the business. Here are some commonly used inventory valuation methods:

Weighted Average Cost Method

The weighted average cost method calculates the average cost of inventory items by considering the cost of each item and the number of units purchased. The average cost is then used to value the ending inventory.

Weighted Average Cost = (Total Cost of Goods Purchased) / (Total Units Purchased)

Specific Identification Method

The specific identification method assigns a unique cost to each inventory item. This method is often used for high-value items or when the cost of each item is significantly different. The advantage of this method is that it provides accurate cost information for each item.

Last-In, First-Out (LIFO) Method

The LIFO method assumes that the most recently purchased inventory items are sold first. This method can result in lower reported profits during periods of rising prices and higher reported profits during periods of falling prices. LIFO can also have tax implications, as it can lead to lower taxable income in periods of rising prices.

Lower of Cost or Market (LCM) Method, Business inventory management

The LCM method values inventory at the lower of its cost or its market value. This method ensures that the inventory is not overvalued and that any potential losses are recognized. The LCM method is often used for inventory items that are subject to price fluctuations or obsolescence.

Outcome Summary: Business Inventory Management

In conclusion, business inventory management is a multifaceted discipline that requires careful planning, execution, and continuous improvement. By implementing effective inventory management strategies, businesses can optimize their inventory levels, reduce costs, improve customer service, and gain a competitive advantage in the marketplace.

myhomeorganic.com

myhomeorganic.com