Delve into the realm of business inventory management systems, indispensable tools that empower businesses to streamline their operations, optimize inventory levels, and gain a competitive edge in today’s dynamic market landscape.

These systems serve as the backbone of inventory management, providing a comprehensive suite of features and functions that cater to the unique needs of various industries and business sizes.

Inventory Management System Overview

A business inventory management system is a software application that helps businesses track and manage their inventory levels. This can include raw materials, work-in-progress, and finished goods. Inventory management systems can help businesses improve their efficiency and profitability by reducing waste, optimizing stock levels, and improving customer service.

There are many different types of inventory management systems available, each with its own strengths and weaknesses. Some of the most common types of inventory management systems include:

- Periodic inventory systemstrack inventory levels at regular intervals, such as monthly or quarterly. This type of system is relatively simple to implement and maintain, but it can be less accurate than other types of systems.

- Perpetual inventory systemstrack inventory levels in real time. This type of system is more accurate than periodic inventory systems, but it can be more complex to implement and maintain.

- Hybrid inventory systemscombine elements of both periodic and perpetual inventory systems. This type of system can be a good compromise between accuracy and complexity.

Features and Functions of Inventory Management Systems

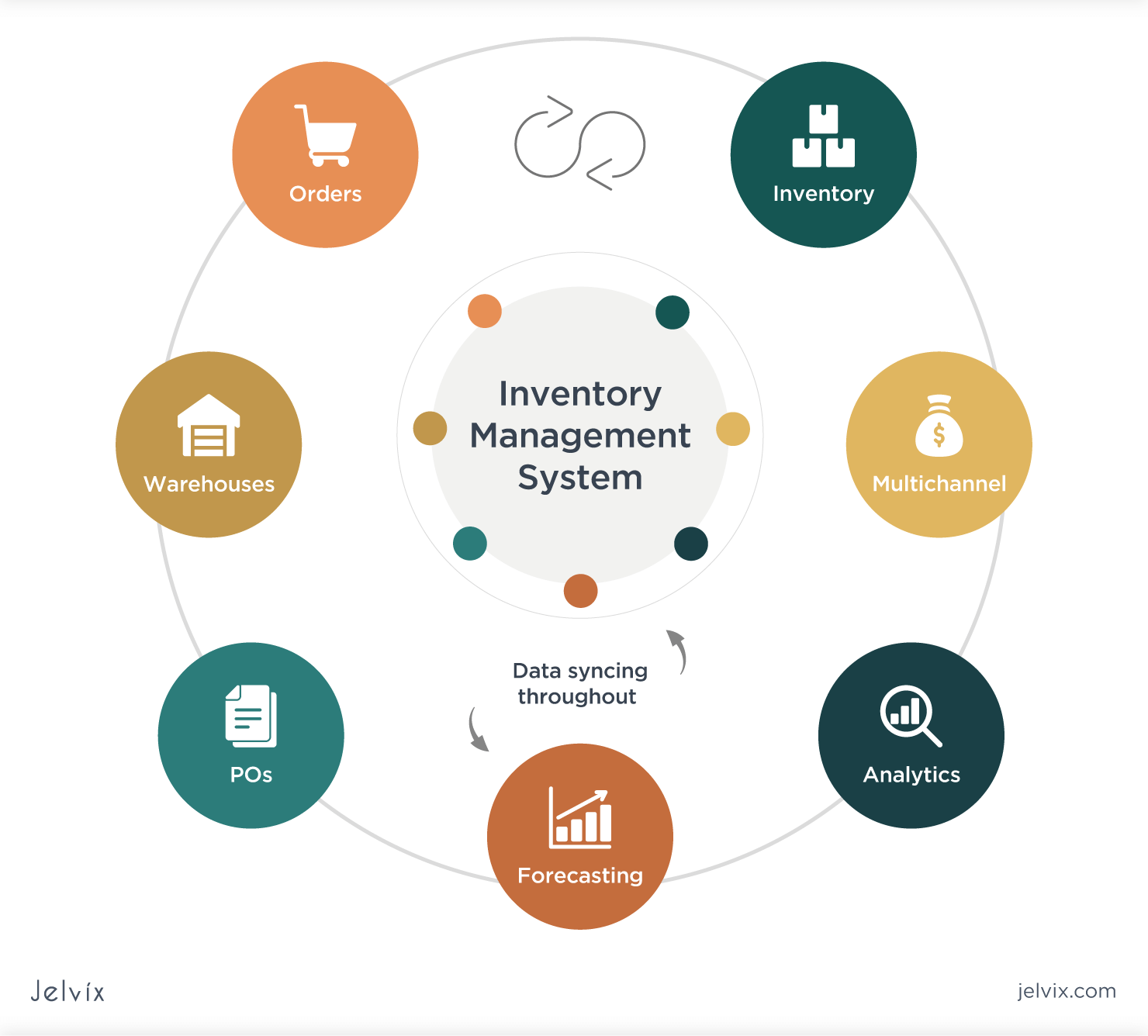

Inventory management systems (IMS) are designed to streamline and optimize inventory-related processes within businesses. They offer a range of core features and functionalities that empower organizations to effectively manage their inventory, including:

- Centralized inventory data: IMSs provide a central repository for all inventory-related information, enabling businesses to have a comprehensive view of their stock levels, locations, and other relevant details.

- Automated inventory tracking: These systems automate the process of tracking inventory movements, including receipts, shipments, adjustments, and returns. This eliminates manual errors and provides real-time visibility into inventory levels.

- Inventory optimization: IMSs use algorithms and data analysis to optimize inventory levels, ensuring that businesses have the right amount of stock to meet demand while minimizing waste and carrying costs.

- Demand forecasting: Some IMSs incorporate demand forecasting capabilities, which help businesses predict future demand based on historical data, market trends, and other factors. This information can be used to make informed decisions about inventory replenishment and avoid stockouts.

- Reporting and analytics: IMSs provide robust reporting and analytics capabilities, enabling businesses to generate customized reports on inventory performance, stock levels, and other key metrics. This data can be used to identify trends, make informed decisions, and improve inventory management practices.

Different Functions of Inventory Management Systems

In addition to these core features, IMSs offer a wide range of additional functions that can be tailored to the specific needs of different businesses. These functions include:

- Warehouse management: IMSs can be integrated with warehouse management systems (WMS) to provide a comprehensive solution for managing inventory within warehouses and distribution centers.

- Supplier management: Some IMSs include supplier management capabilities, enabling businesses to manage their relationships with suppliers, track purchase orders, and monitor supplier performance.

- Customer relationship management (CRM): IMSs can be integrated with CRM systems to provide a unified view of customer data and inventory-related information.

- E-commerce integration: IMSs can be integrated with e-commerce platforms to automate inventory updates and ensure that online orders are fulfilled accurately and efficiently.

- Mobile access: Many IMSs offer mobile apps, allowing users to access inventory data and perform key tasks on the go.

Comparison of Key Features and Functions of Different Inventory Management Systems

The specific features and functions offered by different IMSs can vary significantly. To help businesses make informed decisions, it is important to compare the key features and functions of different systems. The following table provides a comparison of some of the most popular IMSs on the market:| Feature/Function | IMS 1 | IMS 2 | IMS 3 ||—|—|—|—|| Centralized inventory data | Yes | Yes | Yes || Automated inventory tracking | Yes | Yes | Yes || Inventory optimization | Yes | Yes | No || Demand forecasting | Yes | No | Yes || Reporting and analytics | Yes | Yes | Yes || Warehouse management integration | Yes | No | Yes || Supplier management | Yes | No | No || Customer relationship management (CRM) integration | Yes | No | No || E-commerce integration | Yes | Yes | No || Mobile access | Yes | Yes | Yes |

Benefits of Inventory Management Systems: Business Inventory Management System

Inventory management systems (IMSs) provide numerous benefits for businesses, helping them improve efficiency, reduce costs, and gain a competitive edge.

Improved Efficiency, Business inventory management system

IMSs automate many inventory management tasks, such as tracking stock levels, processing orders, and generating reports. This automation reduces manual labor, eliminates errors, and speeds up processes. As a result, businesses can improve their overall efficiency and productivity.

Cost Savings

IMSs can help businesses save costs in several ways. By optimizing inventory levels, businesses can reduce the amount of inventory they hold, which lowers storage costs. IMSs also help businesses avoid overstocking and understocking, which can lead to losses due to spoilage or obsolescence.

Improved Customer Service

IMSs can help businesses improve customer service by ensuring that they have the right products in stock when customers need them. This reduces the risk of lost sales and improves customer satisfaction.

Future Trends in Inventory Management

The future of inventory management is being shaped by emerging technologies and evolving business practices. These trends are transforming the way businesses manage their inventory, enabling them to optimize efficiency, reduce costs, and improve customer satisfaction.

One of the most significant trends is the adoption of cloud-based inventory management systems. Cloud-based systems offer a number of advantages over traditional on-premise systems, including increased flexibility, scalability, and accessibility. They also allow businesses to access their inventory data from anywhere, at any time.

Another trend is the use of artificial intelligence (AI) and machine learning (ML) to automate inventory management tasks. AI and ML can be used to forecast demand, optimize inventory levels, and identify trends. This can help businesses to reduce waste and improve efficiency.

The Internet of Things (IoT)

The Internet of Things (IoT) is also having a major impact on inventory management. IoT devices can be used to track inventory in real time, providing businesses with a more accurate and up-to-date view of their inventory levels. This can help businesses to avoid stockouts and overstocking.

Radio Frequency Identification (RFID)

Radio Frequency Identification (RFID) is another technology that is being used to improve inventory management. RFID tags can be attached to inventory items, allowing them to be tracked throughout the supply chain. This can help businesses to reduce theft and improve inventory accuracy.

These are just a few of the trends that are shaping the future of inventory management. As technology continues to evolve, we can expect to see even more innovative and efficient ways to manage inventory.

Epilogue

In conclusion, business inventory management systems are essential for businesses seeking to enhance efficiency, reduce costs, and gain real-time visibility into their inventory levels. By embracing these systems, businesses can unlock the potential for optimized operations, improved customer satisfaction, and increased profitability.