Embark on a journey into the realm of business inventory control software, an indispensable tool that empowers businesses to optimize stock levels, reduce waste, and elevate inventory accuracy. Dive into this comprehensive guide as we unravel the intricacies of inventory management, exploring its benefits, types, implementation strategies, and best practices.

Uncover how businesses can leverage inventory control systems to streamline operations, enhance efficiency, and unlock a world of data-driven insights for informed decision-making.

Definition of Business Inventory Control Software

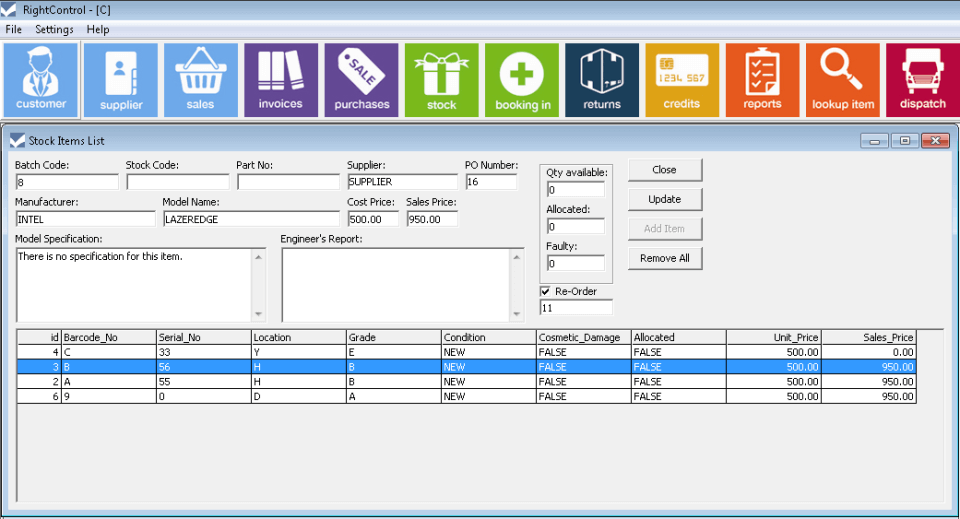

Business inventory control software is a computerized system that helps businesses manage their inventory levels. It provides real-time visibility into inventory levels, enabling businesses to make informed decisions about purchasing, production, and distribution.

Inventory control systems typically include the following features and capabilities:

Key Features and Capabilities

- Inventory tracking:Tracks inventory levels in real-time, providing businesses with an accurate picture of what they have on hand.

- Reorder point management:Sets reorder points for each item, ensuring that businesses never run out of stock.

- Purchase order management:Automates the purchase order process, making it easier to order and receive inventory.

- Warehouse management:Manages inventory in multiple warehouses, providing businesses with a consolidated view of their inventory levels.

- Reporting:Provides a variety of reports, such as inventory turnover, stock levels, and reorder points.

Benefits of Using Business Inventory Control Software

Implementing inventory control software offers numerous advantages for businesses, including enhanced efficiency, reduced costs, and improved customer satisfaction. Inventory control systems streamline inventory management processes, providing real-time visibility into stock levels, order fulfillment, and supplier performance.

Improved Efficiency

Inventory control software automates inventory management tasks, eliminating manual processes and reducing the risk of errors. Automated processes for order processing, stock replenishment, and inventory tracking free up staff time, allowing them to focus on more strategic tasks. The centralized nature of inventory control systems provides a single source of truth for inventory data, eliminating discrepancies and improving communication between departments.

Reduced Costs

Inventory control software helps businesses optimize inventory levels, reducing the risk of overstocking and understocking. Accurate inventory data enables businesses to make informed decisions about purchasing and production, minimizing waste and spoilage. Additionally, inventory control systems can identify slow-moving or obsolete items, allowing businesses to clear out excess inventory and reduce carrying costs.

Enhanced Customer Satisfaction

Inventory control software improves customer satisfaction by ensuring product availability and timely order fulfillment. Real-time inventory visibility allows businesses to monitor stock levels and identify potential shortages, preventing customer disappointment and lost sales. Additionally, inventory control systems can provide customers with online access to inventory information, empowering them to track the status of their orders and make informed purchasing decisions.

Case Study: Acme Corporation

Acme Corporation, a leading manufacturer of electronic components, implemented an inventory control software solution to streamline its inventory management processes. The software automated order processing, stock replenishment, and inventory tracking, reducing manual labor by 50%. The centralized inventory data improved communication between departments, resulting in a 20% reduction in order fulfillment time.

Acme Corporation also reduced its inventory carrying costs by 15% by optimizing inventory levels and identifying slow-moving items.

Features to Consider When Choosing Business Inventory Control Software

Choosing the right inventory control software for your business is crucial for efficient inventory management. Here’s a checklist of essential features to consider:

Evaluating different software options based on your specific business needs is vital. Consider factors such as the size of your inventory, the complexity of your supply chain, and your budget. By carefully considering these features and aligning them with your business requirements, you can select software that empowers your inventory management and drives business success.

Real-Time Inventory Tracking

Real-time inventory tracking provides accurate and up-to-date information on your inventory levels. This feature allows you to:

- Monitor stock levels across multiple locations

- Identify potential stockouts and overstocking

- Optimize inventory levels to minimize costs

Automated Reordering

Automated reordering streamlines the process of replenishing inventory. This feature:

- Sets reorder points based on historical demand and lead times

- Generates purchase orders automatically when stock levels fall below the reorder point

- Ensures timely inventory replenishment and minimizes stockouts

Inventory Forecasting

Inventory forecasting helps predict future demand based on historical data. This feature enables you to:

- Plan for future inventory needs

- Adjust inventory levels to meet changing demand

- Minimize the risk of overstocking or stockouts

Warehouse Management

Warehouse management features support efficient inventory storage and retrieval. These features include:

- Bin and location tracking for precise inventory organization

- Barcode scanning for fast and accurate inventory tracking

- First-in, first-out (FIFO) and last-in, first-out (LIFO) inventory valuation methods

Reporting and Analytics

Reporting and analytics features provide insights into your inventory performance. These features allow you to:

- Track inventory turnover rates

- Identify slow-moving or obsolete items

- Make informed decisions based on data-driven insights

Implementation of Business Inventory Control Software

Implementing business inventory control software can streamline inventory management, enhance accuracy, and optimize operations. The process involves careful planning, execution, and ongoing monitoring to ensure a successful integration.

Steps Involved in Implementation

- Define Objectives and Requirements:Determine the specific goals and needs for implementing the software, considering factors such as inventory size, complexity, and desired outcomes.

- Select and Procure Software:Research and evaluate different software options based on features, cost, and compatibility with existing systems. Acquire the necessary licenses and hardware.

- Data Migration and Integration:Import existing inventory data into the new software and establish integrations with other business systems (e.g., accounting, sales).

- Training and User Adoption:Provide comprehensive training to all users involved in inventory management, ensuring they understand the software’s functionality and best practices.

- Implementation and Monitoring:Deploy the software, monitor its performance, and make adjustments as needed. Track key metrics and identify areas for improvement.

Challenges and Best Practices

Challenges:

- Data Accuracy and Integrity:Ensuring the accuracy of imported data and maintaining data integrity throughout the implementation process.

- User Adoption:Overcoming resistance to change and ensuring users embrace the new software and its processes.

- Integration with Existing Systems:Establishing seamless integrations with other business systems to avoid data silos and streamline operations.

Best Practices:

- Phased Implementation:Implement the software in stages to minimize disruption and allow for gradual user adoption.

- Clear Communication:Communicate the benefits and expectations of the new software to all stakeholders, addressing concerns and fostering buy-in.

- Ongoing Training and Support:Provide ongoing training and support to users, addressing questions and ensuring proficiency.

Tips for Successful Implementation

- Involve key stakeholders throughout the process to ensure alignment and buy-in.

- Establish clear roles and responsibilities for data management and software maintenance.

- Use a data validation tool to ensure the accuracy and completeness of imported data.

- Provide regular training updates and refresher courses to keep users informed and proficient.

- Continuously monitor and evaluate the software’s performance, making adjustments as needed to optimize its effectiveness.

Integration with Other Business Systems

Integrating inventory control software with other business systems is crucial for streamlining operations and improving efficiency. It enables real-time data sharing, eliminates manual data entry, and provides a comprehensive view of business processes.

Integrating with accounting systems ensures accurate inventory valuation, cost tracking, and financial reporting. ERP integration provides a centralized platform for managing inventory, orders, and customer data. CRM integration enhances customer relationship management by providing visibility into inventory levels and customer purchase history.

Benefits of Integration

- Improved data accuracy and reduced errors

- Elimination of manual data entry and associated labor costs

- Enhanced collaboration and communication between departments

- Real-time visibility into inventory levels and customer demand

- Optimized inventory management and reduced holding costs

Challenges of Integration

- Data compatibility and standardization issues

- Cost and complexity of implementation

- Security concerns and data privacy

- Training and adoption by users

Successful Integrations

Examples of successful integrations include:

- Amazon’s integration of its inventory control system with its CRM, allowing for personalized recommendations and inventory visibility across multiple channels.

- Walmart’s integration of its inventory management system with its ERP, enabling real-time inventory updates and efficient order fulfillment.

Best Practices for Managing Inventory with Business Inventory Control Software

Inventory control software can be a powerful tool for businesses to manage their inventory effectively. By using the software, businesses can track their inventory levels in real-time, optimize stock levels, reduce waste, and improve inventory accuracy.One of the best practices for managing inventory with inventory control software is to use the software to track all inventory items.

This includes both finished goods and raw materials. By tracking all inventory items, businesses can get a clear picture of their inventory levels and identify any potential problems.Another best practice is to use the software to set reorder points. Reorder points are the inventory levels at which a business needs to order more of an item.

By setting reorder points, businesses can avoid stockouts and ensure that they always have enough inventory on hand to meet customer demand.Finally, businesses should use the data from their inventory control systems to make informed decisions. The data can be used to identify trends in inventory levels, forecast demand, and optimize inventory levels.

By using the data effectively, businesses can make better decisions about their inventory and improve their overall profitability.

Techniques for Optimizing Stock Levels

There are a number of techniques that businesses can use to optimize their stock levels. One technique is to use the software to track inventory turnover. Inventory turnover is the number of times that inventory is sold and replaced over a period of time.

By tracking inventory turnover, businesses can identify items that are not selling well and adjust their stock levels accordingly.Another technique is to use the software to perform ABC analysis. ABC analysis is a method of classifying inventory items based on their value and usage.

By performing ABC analysis, businesses can focus their attention on the items that are most important to their business.

Reducing Waste

Inventory control software can also help businesses to reduce waste. By tracking inventory levels in real-time, businesses can identify items that are nearing their expiration date or that are not selling well. These items can then be marked down or sold at a discount to avoid waste.

Improving Inventory Accuracy

Inventory control software can also help businesses to improve inventory accuracy. By using the software to track inventory levels in real-time, businesses can reduce the risk of errors in inventory counts. Additionally, the software can help businesses to identify and correct any discrepancies in inventory levels.

Emerging Trends in Business Inventory Control Software

The business landscape is constantly evolving, and inventory control software is no exception. Emerging technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) are revolutionizing the way businesses manage their inventory.

These advancements are enabling inventory control software to become more intelligent and efficient, providing businesses with a range of benefits, including improved accuracy, reduced costs, and enhanced decision-making.

Artificial Intelligence and Machine Learning, Business inventory control software

AI and ML algorithms are being integrated into inventory control software to automate tasks, improve forecasting, and optimize inventory levels. These algorithms can analyze historical data, identify patterns, and make predictions, helping businesses make informed decisions about their inventory.

For example, AI-powered inventory control software can automatically adjust inventory levels based on demand patterns, ensuring that businesses always have the right amount of stock on hand.

Internet of Things

IoT devices, such as sensors and RFID tags, are being used to track inventory in real-time. This data can be integrated into inventory control software, providing businesses with a complete view of their inventory levels.

IoT-enabled inventory control software can also be used to automate tasks such as stock replenishment and order fulfillment, reducing the need for manual intervention.

The Future of Inventory Control Software

The future of inventory control software is bright. As AI, ML, and IoT continue to develop, inventory control software will become even more intelligent and efficient.

Businesses that adopt these emerging technologies will be able to gain a competitive advantage by improving their inventory management practices and reducing costs.

Outcome Summary

As we conclude our exploration of business inventory control software, it becomes evident that this transformative technology is a cornerstone for businesses seeking to gain a competitive edge in today’s dynamic market landscape. By embracing inventory control systems, businesses can unlock the potential for seamless inventory management, reduced costs, and enhanced profitability.

The future of inventory control software holds exciting prospects, with advancements in artificial intelligence, machine learning, and IoT poised to revolutionize the way businesses manage their inventory. Stay tuned for the latest innovations and embrace the transformative power of inventory control software.

myhomeorganic.com

myhomeorganic.com