Welcome to the realm of business inventory systems, where efficient management is the key to unlocking operational success. This comprehensive guide delves into the intricacies of inventory management, empowering you with the knowledge and strategies to optimize your inventory levels, reduce costs, and enhance customer satisfaction.

As we embark on this journey, we will explore the fundamental principles, types, and benefits of inventory management systems. We will uncover the techniques for optimizing inventory levels, forecasting demand, and controlling stock to prevent shortages and overstocking. Additionally, we will delve into inventory valuation, reporting, and best practices to ensure your inventory management aligns with industry standards and drives business growth.

Inventory Optimization

Inventory optimization is the process of determining the optimal levels of inventory to hold to meet customer demand while minimizing costs. This involves balancing the trade-off between the costs of holding inventory (such as storage, insurance, and spoilage) and the costs of stockouts (such as lost sales, backorders, and customer dissatisfaction).

Techniques for Inventory Optimization

There are a number of techniques that can be used to optimize inventory levels. These include:

- ABC analysis: This technique classifies inventory items into three categories (A, B, and C) based on their annual dollar usage. A-items are the most valuable items and should be managed closely to avoid stockouts. B-items are less valuable but still important, and C-items are the least valuable and can be managed with less attention.

- EOQ (Economic Order Quantity): This formula calculates the optimal order quantity for an inventory item, taking into account the costs of holding inventory and the costs of placing orders.

- ROP (Reorder Point): This formula calculates the point at which an inventory item should be reordered to avoid stockouts.

- Safety stock: This is a buffer of inventory that is held to protect against unexpected increases in demand or delays in delivery.

Strategies for Reducing Inventory Costs

There are a number of strategies that can be used to reduce inventory costs while maintaining customer service. These include:

- Vendor-managed inventory (VMI): This is a strategy in which the supplier manages the inventory levels for a customer. This can help to reduce the customer’s inventory costs and improve customer service.

- Just-in-time (JIT) inventory: This is a strategy in which inventory is delivered to a customer just in time for use. This can help to reduce the customer’s inventory costs and improve cash flow.

- Consignment inventory: This is a strategy in which a supplier allows a customer to store inventory at the customer’s location without taking ownership of the inventory. This can help to reduce the customer’s inventory costs and improve flexibility.

The Use of Technology in Inventory Optimization

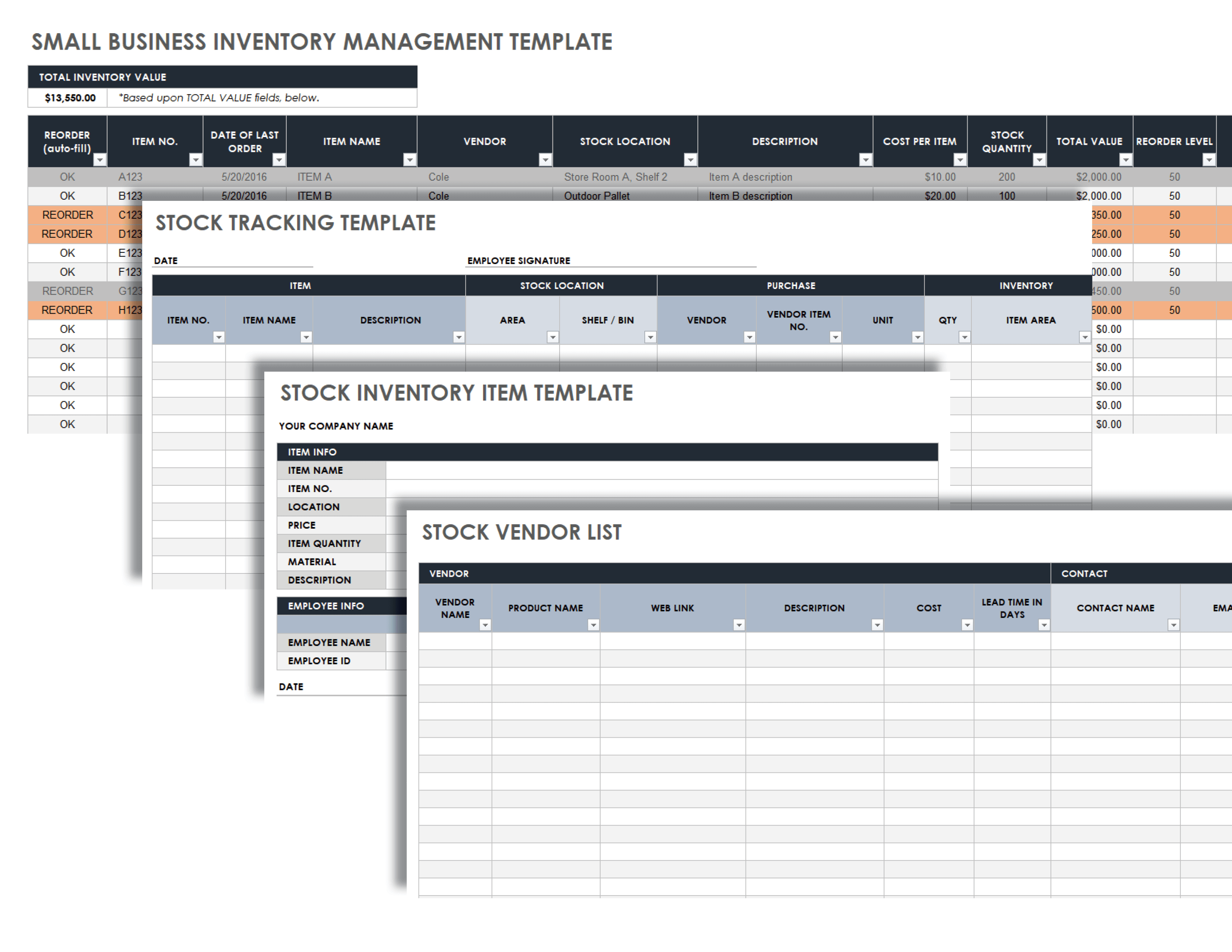

Technology can be a valuable tool for inventory optimization. There are a number of software programs available that can help businesses to track inventory levels, forecast demand, and optimize order quantities. These programs can help businesses to reduce inventory costs and improve customer service.

Inventory Forecasting

Inventory forecasting is a critical process for businesses to predict future demand for their products and optimize their inventory levels. Accurate inventory forecasting enables businesses to avoid stockouts, reduce carrying costs, and improve customer satisfaction.

Methods Used to Forecast Inventory Demand

- Historical Data Analysis:Analyzing past sales data to identify patterns and trends in demand.

- Time Series Analysis:Using statistical techniques to forecast future demand based on historical data.

- Causal Analysis:Identifying and incorporating external factors that influence demand, such as economic indicators, seasonality, and marketing campaigns.

- Machine Learning:Utilizing algorithms to forecast demand based on large datasets and complex patterns.

Factors that Influence Inventory Forecasting Accuracy

- Data Quality:The accuracy and completeness of historical data.

- Demand Volatility:The extent to which demand fluctuates over time.

- Lead Time:The time required to replenish inventory.

- External Factors:Economic conditions, competition, and supplier reliability.

Examples of How Inventory Forecasting Can Improve Supply Chain Planning, Business inventory system

- Optimized Inventory Levels:Accurate forecasting helps businesses maintain optimal inventory levels, reducing stockouts and overstocking.

- Improved Production Planning:Forecasting enables businesses to plan production schedules to meet forecasted demand, reducing waste and maximizing efficiency.

- Enhanced Customer Service:Accurate forecasting helps businesses avoid stockouts and fulfill customer orders promptly, improving customer satisfaction.

- Reduced Costs:Optimized inventory levels reduce carrying costs, such as storage and insurance, and help businesses avoid losses due to spoilage or obsolescence.

Inventory Control: Business Inventory System

Inventory control involves establishing and maintaining optimal inventory levels to meet customer demand while minimizing costs. It encompasses procedures for monitoring inventory levels, setting reorder points, and implementing techniques to prevent stockouts and overstocking. Effective inventory control ensures efficient warehouse operations and optimal resource utilization.

Stockout Prevention

Stockouts occur when inventory levels fall below customer demand, resulting in lost sales and dissatisfied customers. To prevent stockouts, businesses implement safety stock levels, which are additional inventory units held as a buffer to cover unexpected fluctuations in demand or supply chain disruptions.

Safety stock levels are determined based on factors such as historical demand patterns, lead times, and supplier reliability.

Overstocking Reduction

Overstocking occurs when inventory levels exceed customer demand, leading to increased storage costs, product obsolescence, and potential losses due to spoilage or damage. To reduce overstocking, businesses use inventory control techniques such as just-in-time (JIT) inventory management, which aims to minimize inventory levels by ordering products only when needed.

JIT inventory management requires close coordination with suppliers and efficient supply chain management.

Warehouse Operations Improvement

Effective inventory control improves warehouse operations by:

- Reducing inventory carrying costs by optimizing inventory levels.

- Improving warehouse space utilization by minimizing overstocking.

- Increasing warehouse efficiency by streamlining inventory management processes.

- Enhancing customer satisfaction by preventing stockouts and ensuring timely order fulfillment.

Inventory Reporting

Inventory reporting provides valuable insights into the status and performance of your inventory. It helps you track key metrics, identify trends, and make informed decisions about inventory management.

An effective inventory report should include the following key performance indicators (KPIs):

- Inventory turnover ratio

- Days of inventory on hand

- Inventory carrying costs

- Inventory accuracy

- Stockout rate

To ensure easy readability, organize the report using HTML table tags. This will allow you to present the data in a clear and concise manner.

Dashboard for Decision-Making

In addition to the inventory report, you can also create a dashboard that visualizes inventory data. This dashboard can provide real-time insights into inventory levels, trends, and performance. By leveraging data visualization techniques, you can easily identify areas for improvement and make informed decisions about inventory management.

Conclusion

In conclusion, mastering business inventory systems is a crucial aspect of modern business operations. By embracing the strategies and techniques Artikeld in this guide, you can transform your inventory management into a competitive advantage. From optimizing stock levels to leveraging technology, the insights gained here will empower you to streamline operations, reduce costs, and elevate customer service.

Embrace the power of efficient inventory management and unlock the full potential of your business.