Business inventory ordering stands as a cornerstone of efficient operations, directly impacting customer satisfaction and profitability. This comprehensive guide delves into the intricacies of inventory management, empowering businesses with the knowledge to optimize their inventory levels, enhance customer service, and maximize their bottom line.

From understanding inventory basics to implementing cutting-edge optimization techniques, this guide provides a roadmap for businesses to navigate the complexities of inventory management.

Inventory Management Basics

Inventory management is a crucial aspect of business operations, as it directly impacts a company’s financial performance, customer satisfaction, and operational efficiency. It involves the planning, organizing, and controlling of the flow of goods, from their acquisition to their sale or consumption.

Effective inventory management helps businesses optimize their resources, reduce costs, and meet customer demand efficiently. It ensures that the right quantity of inventory is available at the right time, minimizing the risk of stockouts or overstocking.

Types of Inventory, Business inventory ordering

There are various types of inventory, each with its unique characteristics:

- Raw materials:Materials used in the production process.

- Work-in-progress (WIP):Partially completed products.

- Finished goods:Completed products ready for sale.

- Safety stock:Additional inventory held to buffer against unexpected demand fluctuations or supply chain disruptions.

- Cycle stock:Inventory used to meet regular demand during the production or replenishment cycle.

Inventory Valuation Methods

Inventory valuation methods are used to determine the value of inventory on the financial statements. The choice of method can impact a company’s financial reporting and tax liability:

- First-in, first-out (FIFO):Assumes that the oldest inventory is sold first.

- Last-in, first-out (LIFO):Assumes that the most recently acquired inventory is sold first.

- Weighted average cost:Calculates the average cost of inventory on hand, based on the cost of all units purchased during a period.

Inventory Ordering Strategies

Inventory ordering strategies aim to determine the optimal quantity and timing of inventory replenishment to meet customer demand while minimizing costs. There are several strategies to choose from, each with its own advantages and disadvantages.

Reorder Point Model

The reorder point model sets a minimum inventory level (reorder point) at which an order is placed. When inventory falls below this point, a fixed quantity is ordered to bring inventory back to a predetermined level.

Advantages:

- Simple to implement and manage.

- Prevents stockouts by ensuring a minimum inventory level.

Disadvantages:

- May lead to overstocking if demand is lower than expected.

- Can result in stockouts if demand is higher than expected.

Safety Stock Model

The safety stock model maintains a buffer of extra inventory above the reorder point to protect against unexpected increases in demand or supply disruptions.

Advantages:

- Reduces the risk of stockouts.

- Allows for flexibility in responding to changes in demand.

Disadvantages:

- Increases inventory holding costs.

- Can lead to obsolete inventory if demand is overestimated.

Factors Influencing Strategy Choice

The choice of inventory ordering strategy depends on several factors, including:

- Demand variability: The level of uncertainty in customer demand.

- Lead time: The time it takes to receive an order from a supplier.

- Inventory holding costs: The cost of storing inventory.

- Stockout costs: The cost of running out of inventory.

- Service level: The desired level of customer satisfaction in terms of inventory availability.

By considering these factors, businesses can select the inventory ordering strategy that best aligns with their specific needs and objectives.

Inventory Optimization Techniques

Inventory optimization techniques aim to strike a balance between holding sufficient stock to meet customer demand and minimizing inventory-related costs. This involves determining the optimal inventory levels for each item, considering factors such as demand patterns, lead times, and carrying costs.

Technology in Inventory Management

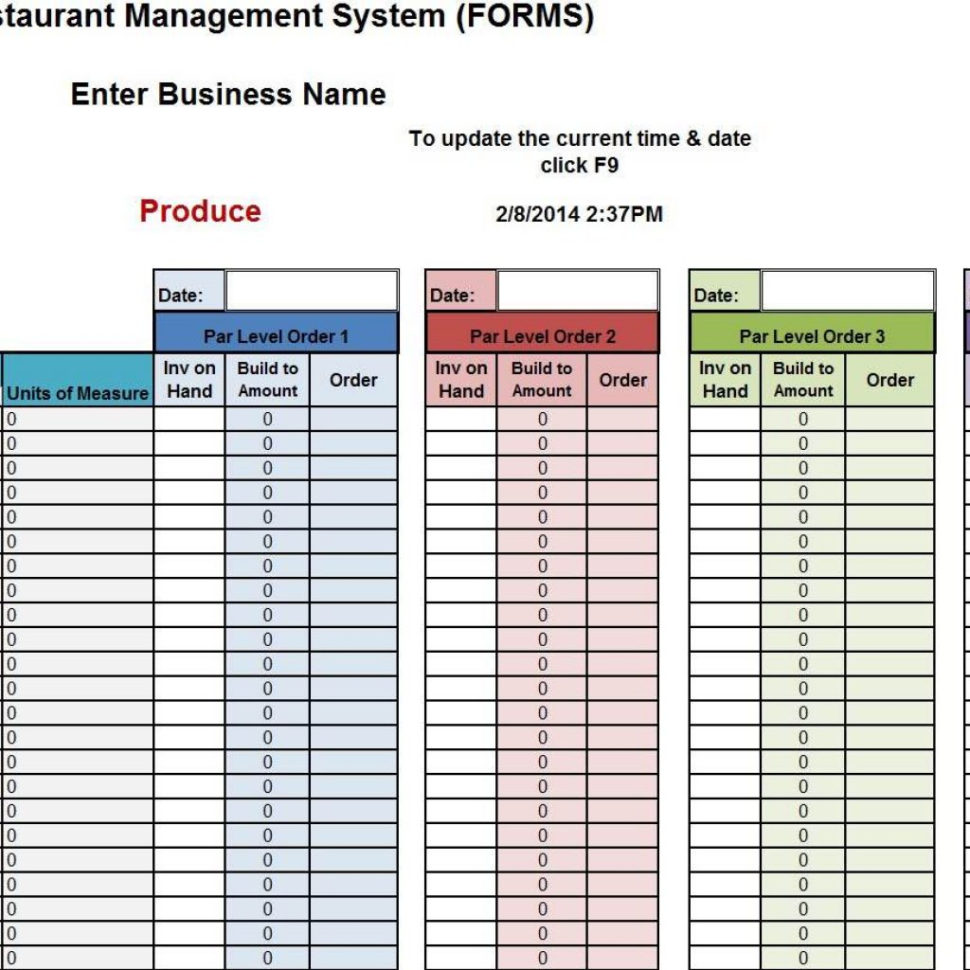

Technology plays a crucial role in inventory optimization. Inventory management software provides real-time visibility into inventory levels, automates ordering processes, and generates reports for analysis. RFID (Radio Frequency Identification) tracking systems use tags attached to inventory items to track their location and movement, providing accurate and up-to-date inventory data.

Implementing Inventory Optimization Techniques

- Analyze Demand Patterns:Study historical sales data to identify demand patterns, seasonality, and trends. This information helps determine safety stock levels and reorder points.

- Set Safety Stock Levels:Establish a minimum inventory level (safety stock) to buffer against unexpected demand fluctuations or supply chain disruptions.

- Calculate Reorder Points:Determine the point at which new inventory should be ordered based on lead times, safety stock levels, and expected demand.

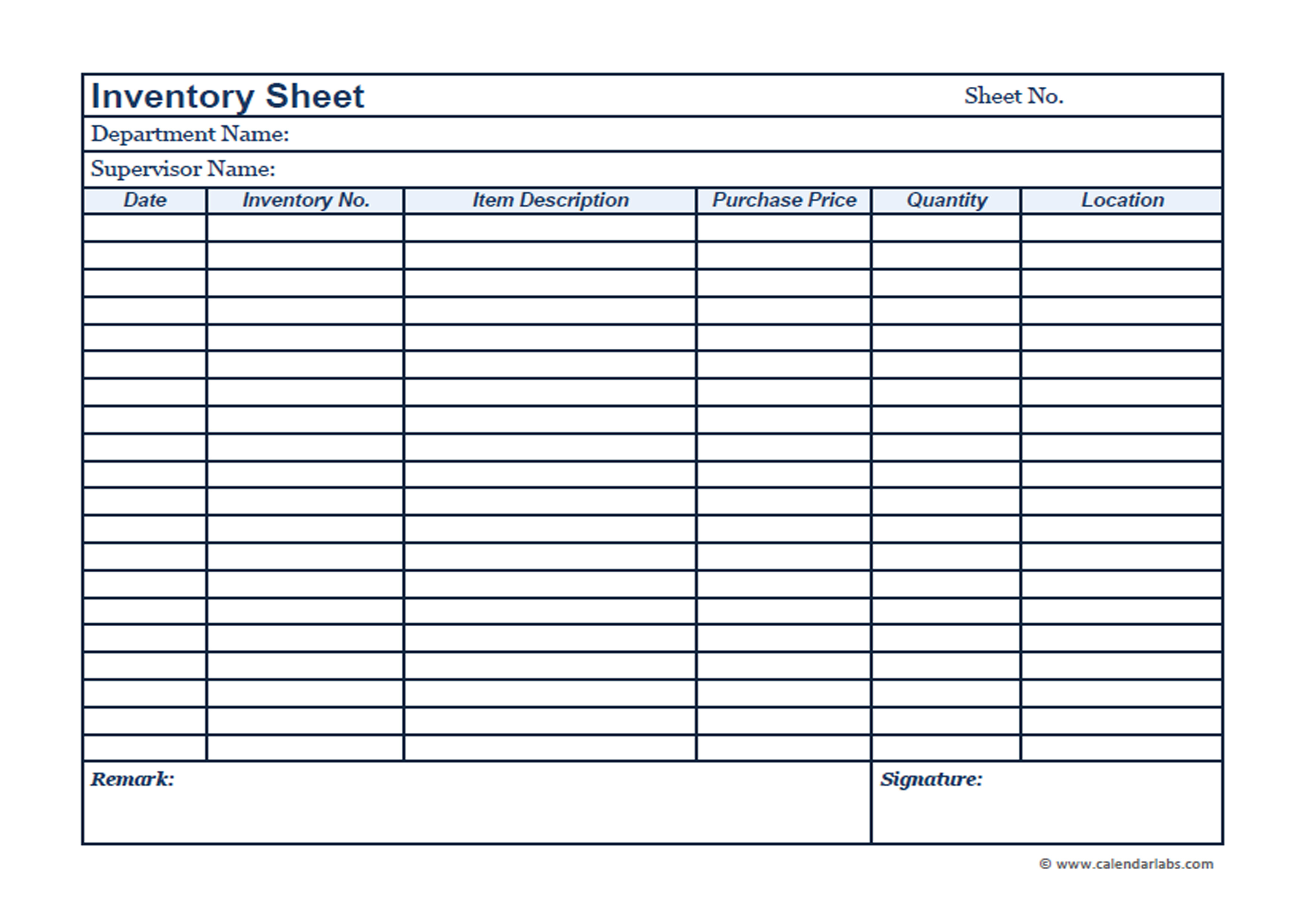

- Implement Inventory Management Software:Use technology to automate inventory tracking, ordering, and reporting, improving accuracy and efficiency.

- Monitor and Adjust:Regularly review inventory levels, demand patterns, and costs to make adjustments to optimization strategies as needed.

Inventory Performance Metrics

Inventory performance metrics are essential for evaluating the effectiveness of your inventory management strategies. These metrics provide valuable insights into how efficiently you’re managing your inventory, helping you identify areas for improvement and optimize your operations.

Inventory Turnover

Inventory turnover measures how quickly your inventory is being sold and replaced. A high inventory turnover rate indicates that you’re effectively managing your inventory, while a low rate suggests that you may have excess inventory on hand.

Inventory Turnover = Cost of Goods Sold / Average Inventory Value

To calculate the average inventory value, you can use the following formula:

Average Inventory Value = (Beginning Inventory Value + Ending Inventory Value) / 2

Inventory Days on Hand

Inventory days on hand measures the average number of days that inventory is held before being sold. A high inventory days on hand value indicates that you may be holding too much inventory, while a low value suggests that you may be at risk of stockouts.

Inventory Days on Hand = (Average Inventory Value / Cost of Goods Sold)

365

By tracking these key inventory performance metrics, you can gain valuable insights into the efficiency of your inventory management practices. This information can help you make informed decisions about your inventory levels, ordering strategies, and other aspects of your inventory management system.

Final Wrap-Up: Business Inventory Ordering

By embracing the principles Artikeld in this guide, businesses can transform their inventory management practices, unlocking the potential for improved efficiency, reduced costs, and enhanced customer loyalty. Remember, effective inventory management is not merely a matter of counting stock; it is a strategic discipline that drives business success.