In the ever-evolving world of e-commerce, business inventory online has emerged as a critical aspect of success. Managing inventory effectively can streamline operations, reduce costs, and enhance customer satisfaction. This comprehensive guide delves into the intricacies of business inventory online, exploring its significance, challenges, and best practices to help businesses optimize their inventory management strategies.

As e-commerce continues to reshape the retail landscape, businesses must embrace innovative inventory management solutions to stay competitive. Business inventory online offers numerous advantages, including real-time inventory tracking, automated order fulfillment, and seamless integration with e-commerce platforms. However, it also presents unique challenges, such as managing multiple sales channels, forecasting demand accurately, and minimizing inventory waste.

Overview of Business Inventory Online

Business inventory refers to the physical goods a company has on hand to meet customer demand. In e-commerce, inventory management plays a critical role in ensuring the availability of products for online purchases.

Managing inventory online offers several benefits, including:

- Improved accuracy:Automated systems reduce errors in inventory counting and tracking.

- Enhanced efficiency:Online platforms streamline inventory processes, saving time and resources.

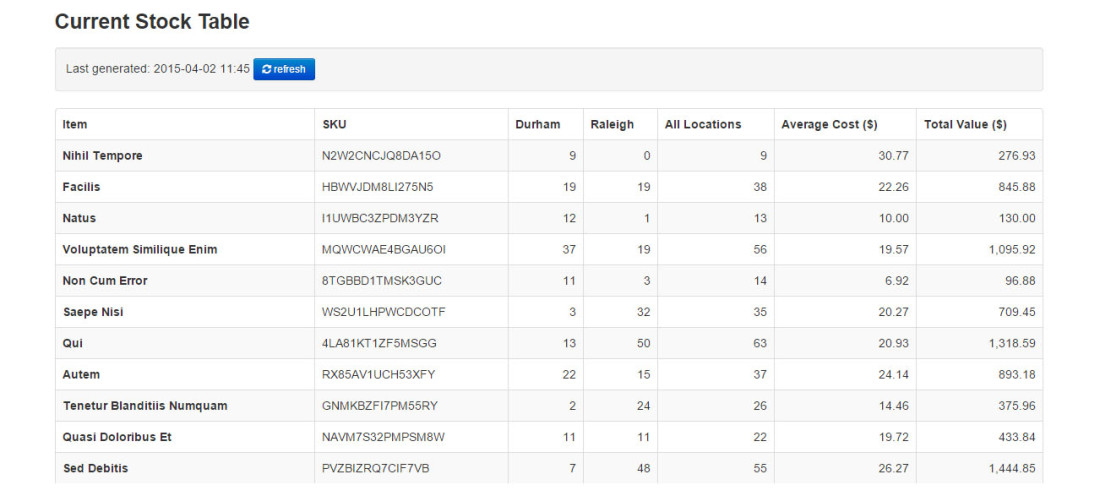

- Increased visibility:Real-time inventory updates provide better control and visibility across multiple channels.

However, there are also challenges associated with online inventory management:

- Stockouts:Inaccurate inventory data can lead to stockouts, resulting in lost sales and customer dissatisfaction.

- Overstocking:Poor inventory forecasting can result in overstocking, tying up cash flow and increasing storage costs.

li> Supply chain disruptions:External factors like supplier delays or transportation issues can impact inventory availability.

Types of Inventory Management Systems

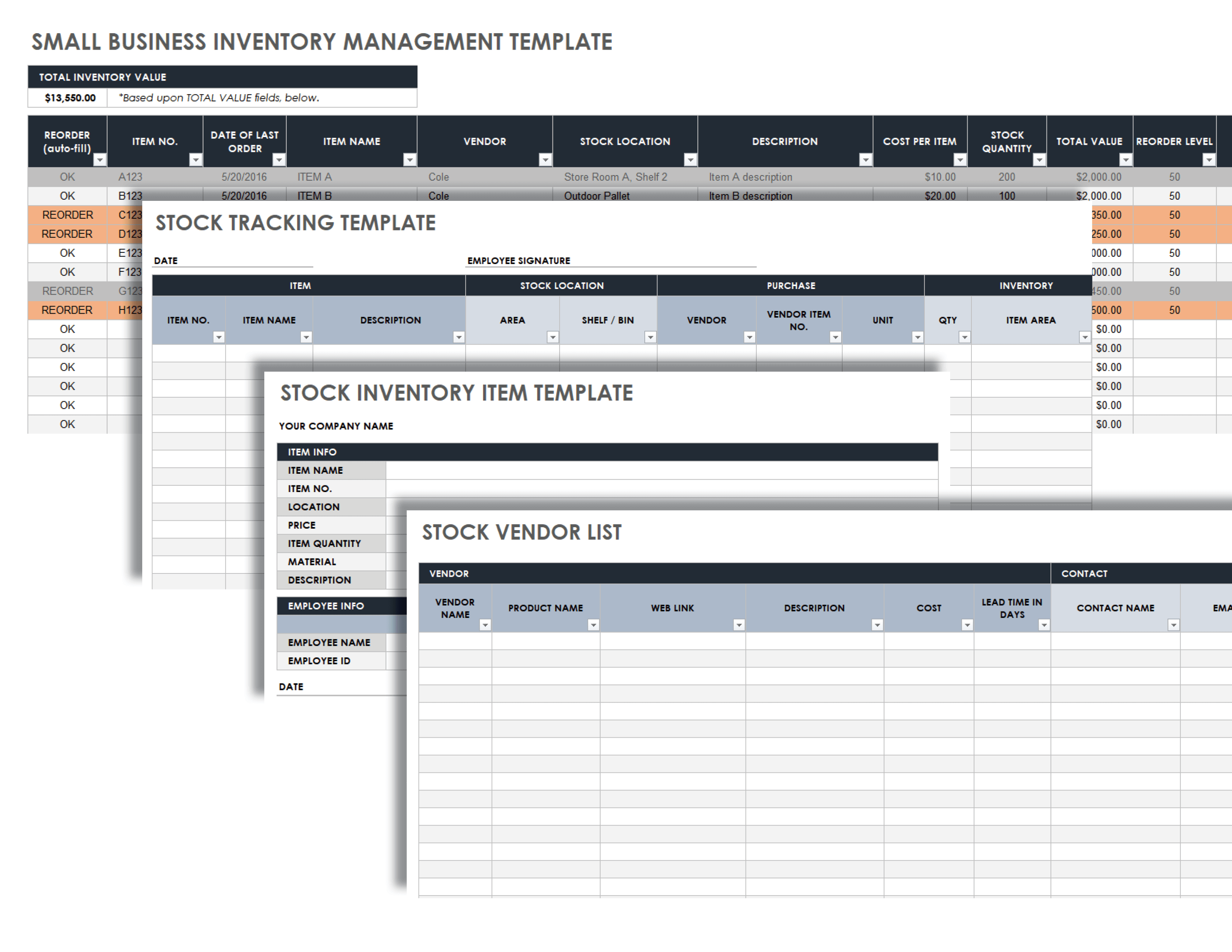

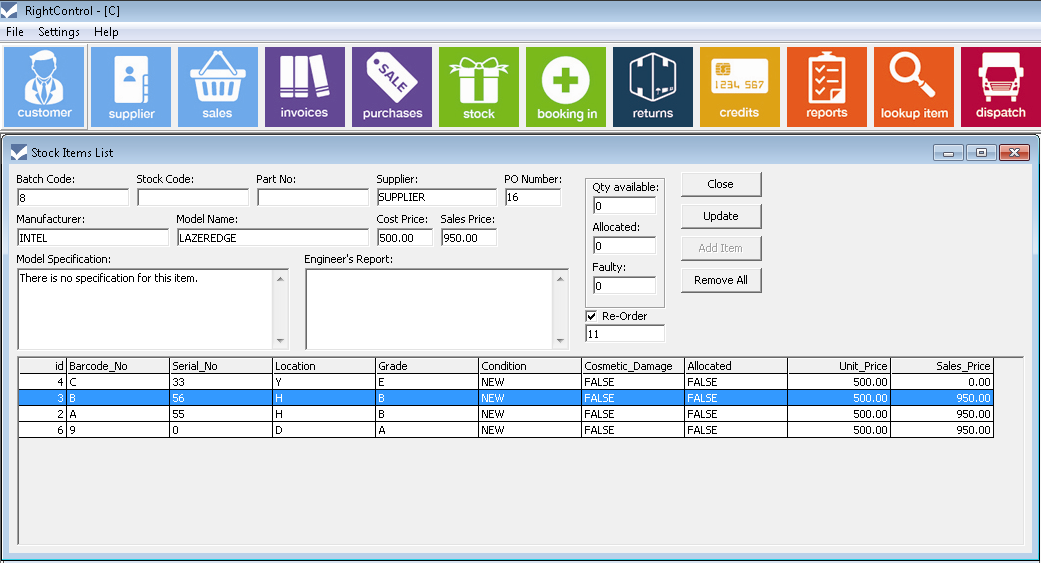

Inventory management systems are crucial for businesses to track and manage their inventory effectively. Different types of inventory management systems exist, each with its own advantages and disadvantages.

Perpetual Inventory System, Business inventory online

A perpetual inventory system continuously tracks inventory levels in real-time. When an item is purchased or sold, the system updates the inventory records immediately. This system provides up-to-date information on inventory levels, allowing businesses to make informed decisions.

- Advantages:

- Accurate and real-time inventory data

- Prevents overstocking or understocking

- Facilitates efficient order fulfillment

- Disadvantages:

- Requires continuous data entry

- Can be complex and expensive to implement

- Relies on accurate data input

Periodic Inventory System

A periodic inventory system tracks inventory levels at specific intervals, such as monthly or quarterly. Physical inventory counts are conducted during these intervals to update inventory records. This system is less complex and less expensive to implement than a perpetual inventory system.

- Advantages:

- Less complex and less expensive to implement

- Suitable for businesses with low inventory turnover

- Provides a snapshot of inventory levels at specific points in time

- Disadvantages:

- Inventory data may not be up-to-date

- Can lead to overstocking or understocking

- May result in delays in order fulfillment

Inventory Optimization and Cost Control

Inventory optimization and cost control are critical aspects of inventory management that directly impact a business’s profitability. By implementing effective strategies, businesses can minimize costs, improve efficiency, and maximize the return on their inventory investment.

Inventory optimization involves finding the optimal balance between inventory levels and customer demand to minimize holding costs while ensuring adequate stock levels to meet customer needs.

Strategies for Inventory Optimization

- Demand Forecasting:Accurately predicting future demand is crucial for optimizing inventory levels. Techniques such as time series analysis and machine learning can help businesses forecast demand based on historical data and market trends.

- Safety Stock Management:Maintaining a buffer stock above the expected demand can help mitigate the risk of stockouts. Safety stock levels should be determined based on factors such as lead time, demand variability, and the cost of stockouts.

- Inventory Turnover:Measuring inventory turnover provides insights into how efficiently inventory is being used. A high inventory turnover indicates efficient inventory management, while a low turnover suggests potential inefficiencies or overstocking.

- ABC Analysis:Classifying inventory items based on their value and usage can help businesses prioritize inventory management efforts. High-value items require closer monitoring and control, while low-value items can be managed with less frequent reviews.

Methods for Reducing Inventory Waste and Improving Turnover

- Just-in-Time (JIT) Inventory:JIT systems aim to minimize inventory levels by receiving inventory only when needed for production or sales. This approach reduces holding costs and improves inventory turnover.

- Vendor Managed Inventory (VMI):In VMI, the supplier manages the inventory levels at the customer’s location. The supplier is responsible for monitoring inventory levels, placing orders, and managing the inventory replenishment process.

- Consignment Inventory:Under consignment inventory, the supplier retains ownership of the inventory until it is sold by the customer. This arrangement reduces the customer’s financial risk and frees up cash flow.

- Periodic Inventory Reviews:Regular inventory reviews help identify obsolete or slow-moving items. These items can be discounted, sold at a loss, or returned to the supplier to reduce inventory waste.

Integration with E-commerce Platforms: Business Inventory Online

Inventory management systems can be integrated with e-commerce platforms to streamline inventory management processes and provide a seamless customer experience. This integration allows businesses to manage their inventory across multiple sales channels, including online marketplaces, retail stores, and their own e-commerce websites.By integrating inventory management systems with e-commerce platforms, businesses can:

Real-time Inventory Updates

Ensure accurate and up-to-date inventory levels across all sales channels, eliminating the risk of overselling or stockouts.

Order Fulfillment Automation

Automate the order fulfillment process by directly connecting the inventory management system to the e-commerce platform. This eliminates manual order processing and reduces errors.

Enhanced Customer Experience

Provide customers with real-time product availability information, allowing them to make informed purchase decisions and reduce frustration caused by out-of-stock items.

Centralized Inventory Management

Manage inventory from a single platform, providing a comprehensive view of stock levels and facilitating efficient inventory allocation.

Improved Sales Forecasting

Analyze sales data from multiple channels to improve demand forecasting and optimize inventory levels to meet customer demand.

Summary

By implementing effective inventory management practices, businesses can optimize their operations, reduce costs, and enhance customer satisfaction. Leveraging technology, integrating with e-commerce platforms, and adopting best practices can empower businesses to gain a competitive edge in the dynamic e-commerce environment.

As inventory management continues to evolve, businesses must stay abreast of emerging trends and embrace innovative solutions to stay ahead of the curve.