Business inventory control software has emerged as an indispensable tool for businesses seeking to streamline their inventory management processes, optimize stock levels, and enhance overall operational efficiency. By leveraging the capabilities of these advanced software solutions, businesses can gain real-time visibility into their inventory, automate tasks, and make informed decisions to reduce costs, minimize waste, and maximize profitability.

This comprehensive guide delves into the multifaceted world of business inventory control software, exploring its benefits, key features, and best practices. We will examine how this technology empowers businesses to achieve inventory accuracy, improve forecasting, optimize warehouse operations, and gain valuable insights through reporting and analytics.

By the end of this exploration, you will have a thorough understanding of how business inventory control software can transform your inventory management practices and drive your business towards success.

Inventory Management Software

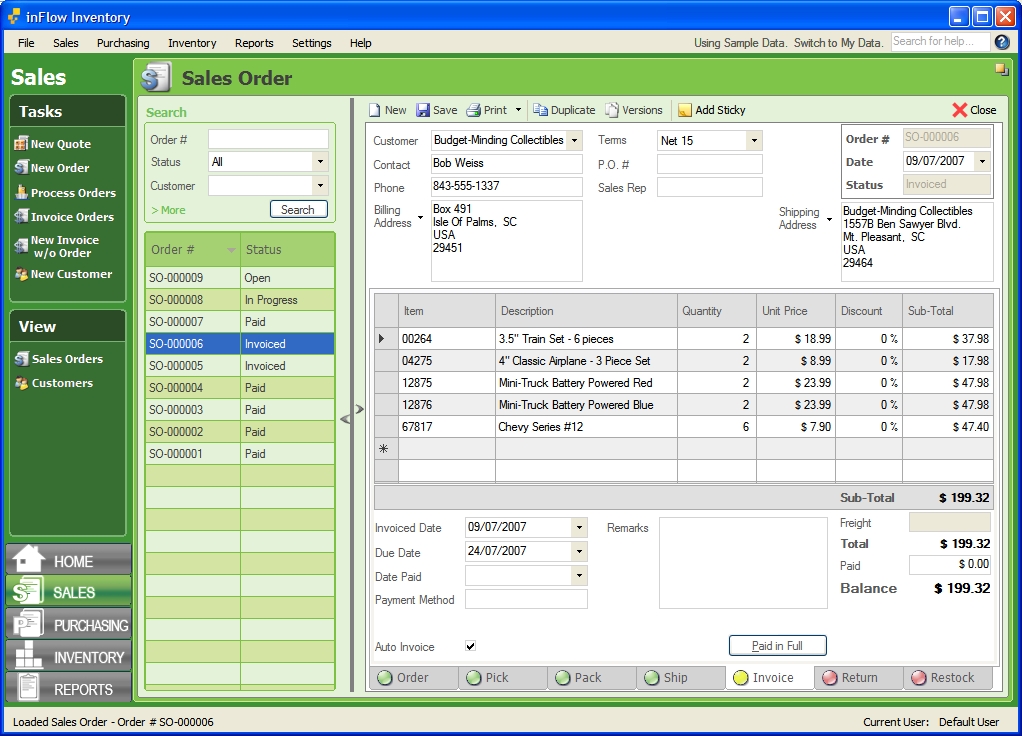

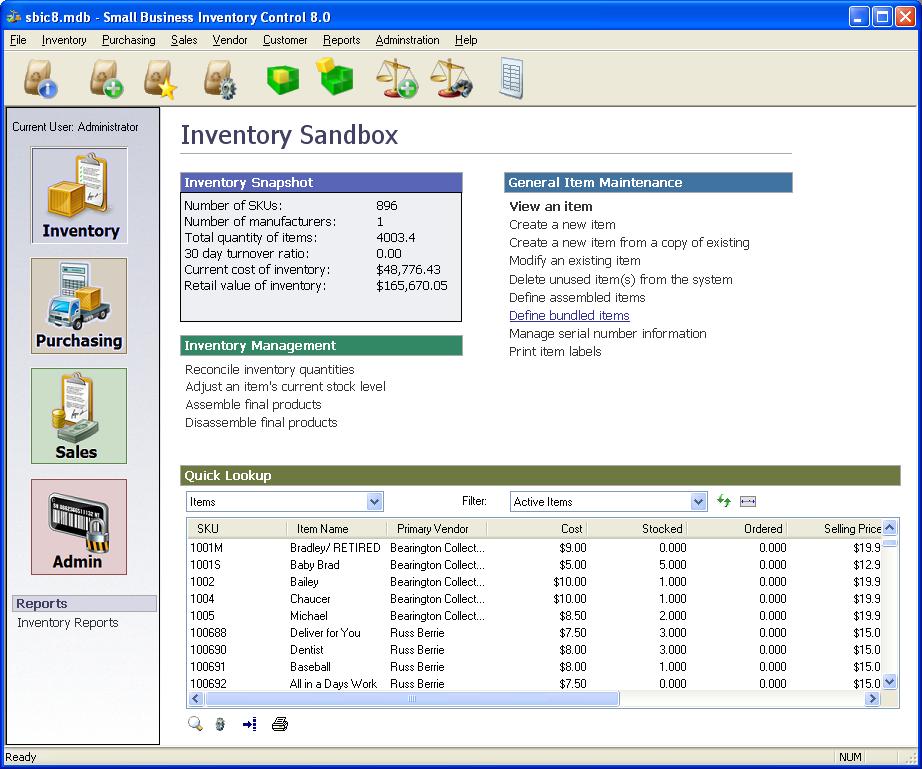

Inventory management software is a powerful tool that can help businesses improve their inventory accuracy and efficiency. This software can automate many of the tasks associated with inventory management, such as tracking inventory levels, managing orders, and generating reports. As a result, businesses can save time and money, while also improving their customer service.

Benefits of Using Inventory Management Software

- Improved inventory accuracy: Inventory management software can help businesses improve their inventory accuracy by providing real-time visibility into their inventory levels. This can help businesses avoid stockouts and overstocking, which can both lead to lost sales and profits.

- Increased efficiency: Inventory management software can help businesses increase their efficiency by automating many of the tasks associated with inventory management. This can free up employees to focus on other tasks, such as sales and customer service.

- Improved customer service: Inventory management software can help businesses improve their customer service by providing them with the information they need to quickly and accurately fulfill orders. This can lead to increased customer satisfaction and loyalty.

Examples of How Inventory Management Software Can Improve Inventory Accuracy and Efficiency

- A retail store can use inventory management software to track the inventory levels of each item in the store. This information can be used to generate reports that show which items are selling well and which items are not.

The store can then use this information to make decisions about which items to stock and how much to order.

- A manufacturing company can use inventory management software to track the inventory levels of raw materials, work-in-process, and finished goods. This information can be used to generate reports that show which items are in short supply and which items are overstocked.

The company can then use this information to make decisions about which items to purchase and how much to produce.

- A distribution center can use inventory management software to track the inventory levels of products that are stored in the warehouse. This information can be used to generate reports that show which products are in high demand and which products are not.

The distribution center can then use this information to make decisions about which products to stock and how much to order.

Key Features to Look for When Selecting Inventory Management Software

- Real-time inventory visibility: The software should provide real-time visibility into inventory levels, so that businesses can always know what they have on hand.

- Automated inventory tracking: The software should be able to automatically track inventory levels, so that businesses can avoid stockouts and overstocking.

- Reporting capabilities: The software should be able to generate reports that show inventory levels, sales trends, and other important information.

- Integration with other business systems: The software should be able to integrate with other business systems, such as accounting and CRM systems.

- Scalability: The software should be scalable, so that it can grow with the business.

Real-Time Inventory Tracking: Business Inventory Control Software

Real-time inventory tracking is a technology that allows businesses to monitor their inventory levels in real-time. This provides a number of advantages, including:

- Improved accuracy:Real-time inventory tracking eliminates the need for manual inventory counts, which can be inaccurate and time-consuming. This can lead to significant cost savings and improved efficiency.

- Reduced stockouts:Real-time inventory tracking can help businesses avoid stockouts by providing them with up-to-date information on their inventory levels. This allows them to take proactive steps to replenish their inventory before it runs out.

- Reduced overstocking:Real-time inventory tracking can also help businesses reduce overstocking by providing them with accurate information on their inventory levels. This allows them to avoid purchasing more inventory than they need, which can save them money and space.

Examples of Businesses That Have Successfully Implemented Real-Time Inventory Tracking

- Amazon:Amazon uses real-time inventory tracking to manage its vast inventory of products. This allows them to keep track of their inventory levels in real-time and avoid stockouts.

- Walmart:Walmart uses real-time inventory tracking to manage its inventory of over 140 million products. This allows them to keep track of their inventory levels in real-time and avoid overstocking.

- Target:Target uses real-time inventory tracking to manage its inventory of over 100 million products. This allows them to keep track of their inventory levels in real-time and reduce stockouts.

Inventory Optimization

Inventory optimization is a crucial aspect of business operations, ensuring that businesses have the right amount of inventory to meet customer demand while minimizing costs. Optimizing inventory levels can significantly impact a company’s profitability, efficiency, and customer satisfaction.

Strategies for Inventory Optimization

- Demand Forecasting:Accurately predicting customer demand is essential for optimal inventory levels. Businesses can use historical data, market trends, and statistical techniques to forecast future demand.

- Safety Stock:Maintaining a buffer of safety stock helps businesses mitigate unexpected demand fluctuations or supply chain disruptions.

- Economic Order Quantity (EOQ):Determining the optimal quantity to order at a time minimizes total inventory costs, including ordering, holding, and shortage costs.

- Inventory Turnover:Tracking inventory turnover rate helps businesses identify slow-moving or obsolete items and adjust inventory levels accordingly.

- Vendor Management:Establishing strong relationships with suppliers and negotiating favorable terms can help reduce lead times and improve inventory availability.

Inventory Control Software and Optimization

Inventory control software plays a vital role in inventory optimization by providing real-time data, automating processes, and generating insights.

- Real-Time Inventory Tracking:Accurate and up-to-date inventory data enables businesses to make informed decisions about stock levels.

- Automated Replenishment:Software can automatically trigger replenishment orders based on pre-defined inventory thresholds, ensuring optimal stock levels.

- Inventory Forecasting:Advanced software can use historical data and predictive analytics to forecast demand and generate optimal inventory plans.

- Data Analysis:Inventory control software provides comprehensive data and reports, helping businesses identify trends, optimize inventory levels, and reduce carrying costs.

Inventory Forecasting

Inventory forecasting plays a crucial role in business inventory control, enabling businesses to anticipate future demand and optimize their inventory levels. Accurate forecasting helps businesses avoid overstocking, which can lead to excess inventory costs and obsolescence, and understocking, which can result in lost sales and customer dissatisfaction.

Methods for Inventory Forecasting

There are several methods used for inventory forecasting, each with its own advantages and disadvantages:

- Historical Data Analysis:This method uses historical sales data to predict future demand. It is relatively simple and straightforward, but it assumes that past trends will continue into the future.

- Trend Analysis:This method identifies trends in historical data to forecast future demand. It is useful when demand is growing or declining over time.

- Causal Analysis:This method uses external factors, such as economic conditions or marketing campaigns, to forecast demand. It is more complex than other methods, but it can be more accurate when external factors are likely to impact demand.

- Machine Learning:This method uses algorithms to analyze large amounts of data and identify patterns. It can be very accurate, but it requires a significant amount of data and expertise to implement.

Inventory Control Software for Forecasting Accuracy

Inventory control software can significantly improve the accuracy of inventory forecasting by:

- Automating data collection and analysis:Software can automatically collect and analyze historical sales data, trend data, and external factors, reducing the risk of human error.

- Providing real-time visibility:Software provides real-time visibility into inventory levels, sales data, and other relevant metrics, allowing businesses to make more informed forecasting decisions.

- Simulating different scenarios:Software can simulate different forecasting scenarios, allowing businesses to test the impact of different assumptions and make more robust forecasts.

- Integrating with other systems:Software can integrate with other business systems, such as ERP systems, to access additional data and improve forecasting accuracy.

Warehouse Management

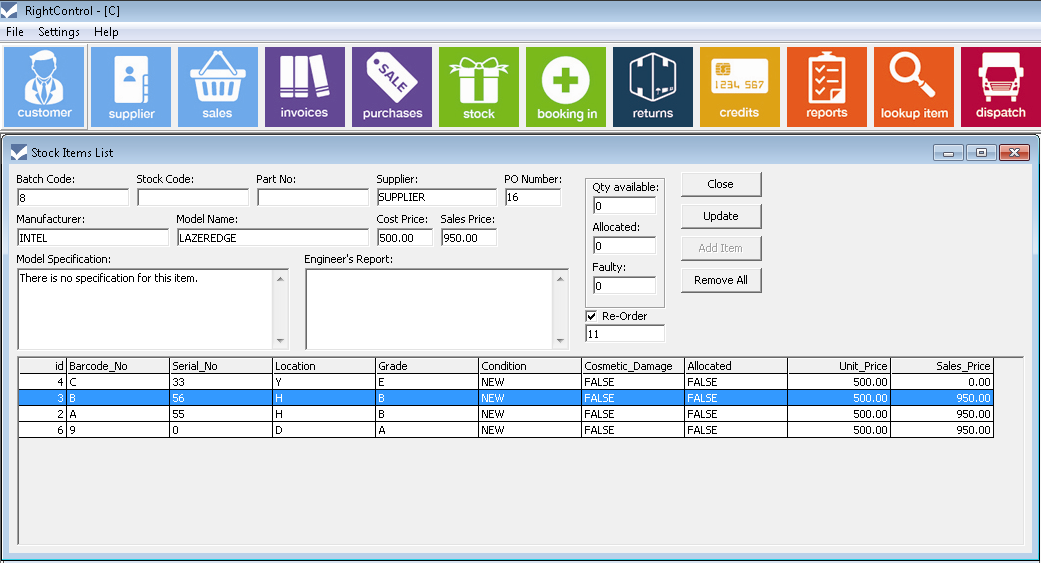

Inventory control software revolutionizes warehouse management by streamlining receiving, picking, and shipping processes. It provides real-time visibility into inventory levels, enabling efficient allocation of resources and minimizing discrepancies.

Receiving Process

- Automates the receiving process, reducing manual data entry and errors.

- Provides mobile scanning capabilities for quick and accurate inventory updates.

- Integrates with barcode scanners to expedite the identification and verification of incoming goods.

Picking Process

- Optimizes picking routes and minimizes travel time within the warehouse.

- Provides real-time updates on inventory availability, preventing over-picking or under-picking.

- Supports various picking methods, such as FIFO, LIFO, and FEFO, to ensure efficient stock rotation.

Shipping Process

- Automates shipping label generation and tracking, reducing errors and expediting order fulfillment.

- Integrates with shipping carriers for seamless package tracking and delivery updates.

- Provides real-time inventory visibility to prevent overselling and ensure accurate order processing.

Managing Multiple Warehouses

- Centralizes inventory data from multiple warehouses, providing a comprehensive view of stock levels.

- Facilitates inter-warehouse transfers to optimize inventory distribution and reduce stock imbalances.

- Enables the establishment of minimum and maximum inventory levels for each warehouse, ensuring optimal stock levels.

Reporting and Analytics

Reporting and analytics are crucial aspects of inventory management, enabling businesses to monitor their inventory levels, identify trends, and make informed decisions to optimize their inventory management practices.

Types of Reports

- Inventory Turnover Report:Tracks the number of times inventory is sold and replaced over a period of time, indicating the efficiency of inventory management.

- Stock Level Report:Provides real-time visibility into current inventory levels, allowing businesses to identify potential stockouts or overstocking situations.

- Demand Forecast Report:Predicts future demand based on historical data and market trends, helping businesses plan their inventory accordingly.

- Purchasing Analysis Report:Analyzes purchasing patterns, identifying potential cost savings and supplier performance issues.

Benefits of Reporting and Analytics

- Improved Decision-Making:Provides data-driven insights to support inventory management decisions, such as optimal inventory levels, reorder points, and safety stock levels.

- Reduced Costs:Helps identify and eliminate waste, such as overstocking or stockouts, leading to reduced inventory carrying costs.

- Increased Sales:Enables businesses to meet customer demand effectively, minimizing lost sales due to stockouts.

- Improved Customer Satisfaction:By maintaining optimal inventory levels, businesses can ensure timely fulfillment of orders, enhancing customer satisfaction.

Cloud-Based Inventory Control

Cloud-based inventory control software provides real-time inventory visibility, allowing businesses to track their inventory levels from anywhere with an internet connection. This eliminates the need for manual inventory tracking, which can be time-consuming and error-prone. Cloud-based inventory control software also offers a number of other advantages, including:

- Improved accuracy: Cloud-based inventory control software uses real-time data to track inventory levels, which helps to eliminate errors and improve accuracy.

- Increased efficiency: Cloud-based inventory control software can automate many inventory management tasks, such as reordering and tracking shipments, which can save businesses time and money.

- Enhanced collaboration: Cloud-based inventory control software allows multiple users to access and update inventory information in real-time, which can improve collaboration and communication.

- Scalability: Cloud-based inventory control software can be easily scaled to meet the needs of growing businesses, which can help businesses save money on hardware and software costs.

Examples of Cloud-Based Inventory Control Software Solutions

There are a number of different cloud-based inventory control software solutions available, including:

- Fishbowl Inventory

- NetSuite Inventory Management

- SAP Business One

- Microsoft Dynamics 365 for Finance and Operations

- Oracle NetSuite

Security Considerations When Using Cloud-Based Inventory Control Software

When using cloud-based inventory control software, it is important to consider the following security considerations:

- Data security: Make sure that the cloud-based inventory control software provider has strong security measures in place to protect your data.

- Access control: Make sure that only authorized users have access to your inventory information.

- Backup and recovery: Make sure that you have a backup plan in place in case of a data loss.

Mobile Inventory Management

In today’s fast-paced business environment, mobile inventory management software has emerged as an essential tool for businesses looking to streamline their inventory operations and improve efficiency.

This software empowers employees with real-time inventory information, enabling them to make informed decisions and respond quickly to changing market demands.

Benefits of Mobile Inventory Management Software

- Real-time inventory tracking: Provides employees with instant access to up-to-date inventory levels, eliminating the need for manual counting and reducing the risk of errors.

- Improved accuracy: Automates inventory updates, eliminating human error and ensuring that inventory records are always accurate.

- Increased efficiency: Streamlines inventory processes, such as receiving, shipping, and cycle counting, saving time and resources.

- Enhanced collaboration: Allows multiple users to access and update inventory information simultaneously, improving communication and coordination.

- Reduced costs: By optimizing inventory levels and minimizing waste, mobile inventory management software can help businesses reduce their operating costs.

Examples of Successful Implementations

- Walmart:Implemented a mobile inventory management system to track inventory levels in its retail stores. This system improved inventory accuracy by 98% and reduced out-of-stocks by 30%.

- Amazon:Uses mobile inventory management software to manage inventory in its warehouses. This system allows Amazon to track inventory levels in real-time and optimize its fulfillment process.

- Starbucks:Implemented a mobile inventory management system to track inventory levels in its coffee shops. This system improved inventory accuracy by 95% and reduced waste by 15%.

Inventory Control Best Practices

Effective inventory control practices are crucial for businesses to maintain optimal stock levels, minimize costs, and enhance customer satisfaction. Implementing these best practices can lead to significant improvements in inventory management, ensuring businesses operate efficiently and profitably.

One key aspect of inventory control is cycle counting. This involves physically counting inventory at regular intervals to verify the accuracy of the records. Cycle counting helps identify discrepancies between the physical inventory and the records, allowing for timely adjustments and improved inventory visibility.

Regular Inventory Audits

Regular inventory audits are another essential best practice. These comprehensive physical counts of the entire inventory are typically conducted annually or semi-annually. Inventory audits provide a detailed snapshot of the inventory status, enabling businesses to identify any discrepancies, obsolete items, or areas for improvement.

Role of Technology

Technology plays a vital role in enhancing inventory control practices. Inventory management software automates many tasks, such as tracking inventory levels, managing purchase orders, and generating reports. Real-time inventory tracking systems provide businesses with up-to-date visibility into their inventory, allowing them to make informed decisions and respond quickly to changes in demand.

Case Studies and Success Stories

Numerous businesses have witnessed remarkable improvements in their inventory management practices by implementing business inventory control software. These case studies and success stories highlight the challenges these businesses faced and how the software helped them overcome these obstacles, leading to significant benefits.

Improved Inventory Accuracy, Business inventory control software

Many businesses struggle with inventory accuracy, resulting in lost revenue, customer dissatisfaction, and operational inefficiencies. Inventory control software has proven effective in addressing this issue by providing real-time visibility into inventory levels, eliminating manual errors, and automating inventory tracking processes.

Enhanced Inventory Optimization

Businesses often face challenges in optimizing their inventory levels, leading to either overstocking or understocking. Inventory control software helps businesses analyze historical data, forecast demand, and set optimal inventory levels to minimize carrying costs, prevent stockouts, and improve cash flow.

Streamlined Warehouse Management

Inefficient warehouse management can lead to delays, errors, and increased costs. Inventory control software integrates with warehouse management systems to provide real-time inventory visibility, optimize warehouse operations, and improve space utilization.

Increased Customer Satisfaction

Accurate inventory management is crucial for fulfilling customer orders on time and in full. By ensuring accurate inventory levels and efficient order fulfillment, inventory control software helps businesses improve customer satisfaction and build stronger relationships.

Reduced Labor Costs

Manual inventory management processes can be time-consuming and error-prone. Inventory control software automates many of these tasks, reducing labor costs, freeing up staff for more strategic initiatives, and improving overall productivity.

Wrap-Up

In conclusion, business inventory control software has revolutionized the way businesses manage their inventory. By embracing the power of these innovative solutions, organizations can unlock a wealth of benefits, including improved accuracy, optimized stock levels, reduced costs, and enhanced decision-making.

As technology continues to advance, we can expect even more sophisticated and feature-rich inventory control software to emerge, empowering businesses to achieve even greater levels of efficiency and profitability.

Top FAQs

What are the key benefits of using business inventory control software?

Business inventory control software offers a wide range of benefits, including improved inventory accuracy, reduced stockouts and overstocking, optimized inventory levels, streamlined warehouse operations, and enhanced reporting and analytics.

How can business inventory control software help businesses improve inventory accuracy?

Inventory control software utilizes real-time tracking and data analysis to provide businesses with a clear and up-to-date view of their inventory levels. This allows businesses to identify and correct discrepancies, reducing errors and ensuring that inventory records are accurate.

What are some best practices for effective inventory control?

Effective inventory control involves implementing regular inventory audits, cycle counting, and utilizing technology to automate tasks and improve accuracy. Additionally, businesses should establish clear inventory policies and procedures, and train staff on proper inventory management practices.