Embark on a comprehensive journey into the realm of business central inventory movement, a crucial aspect of supply chain management. From defining its significance to exploring its impact on business operations, this guide delves into the intricacies of inventory movement, providing invaluable insights and best practices for effective management.

As businesses strive for efficiency and optimization, understanding inventory movement is paramount. This guide equips you with the knowledge and strategies to navigate the complexities of inventory management, ensuring seamless operations and enhanced profitability.

Overview of Business Central Inventory Movement

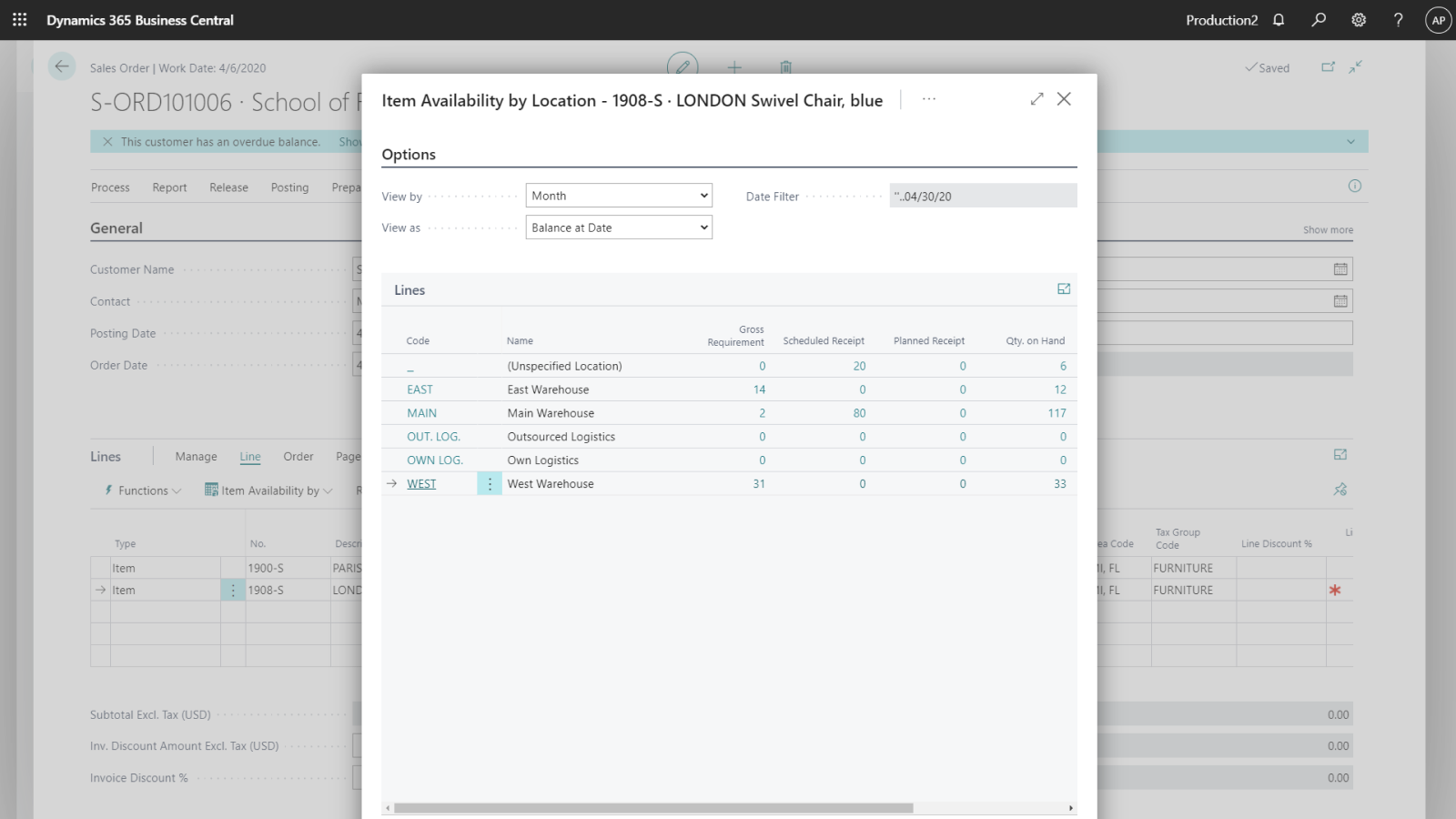

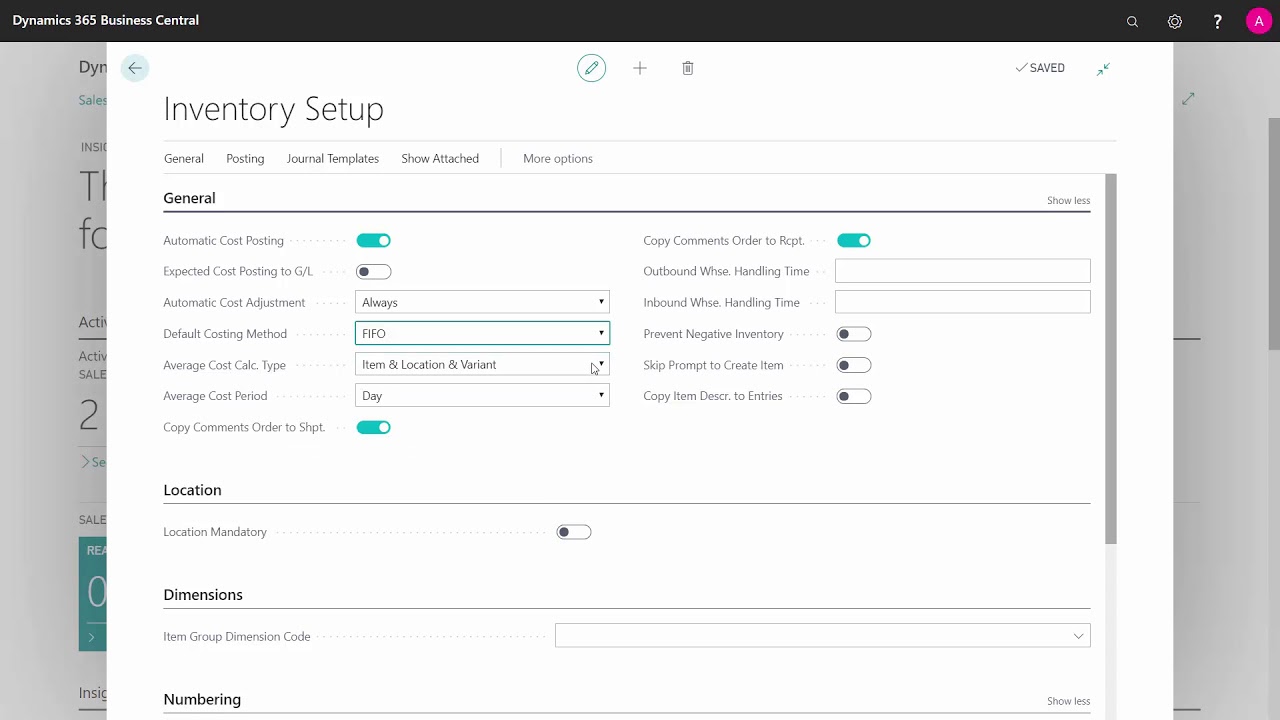

Business Central inventory movement refers to the tracking and management of the flow of goods within a warehouse or supply chain system. It involves the physical movement of inventory items from one location to another, such as from a receiving dock to a storage area or from a warehouse to a retail store.

Inventory movement is a critical aspect of supply chain management as it ensures that the right products are available in the right quantities at the right time to meet customer demand. Efficient inventory movement helps businesses optimize their inventory levels, reduce costs, and improve customer satisfaction.

Real-World Examples of Inventory Movement

Inventory movement occurs in various industries, including:

- Retail:Movement of products from distribution centers to retail stores and from stores to customers.

- Manufacturing:Movement of raw materials from suppliers to production lines and finished goods from production lines to warehouses.

- Healthcare:Movement of medical supplies from suppliers to hospitals and from hospitals to patients.

- Logistics:Movement of goods from one location to another through various transportation modes.

Types of Inventory Movements

Inventory movements are the physical movement of inventory items within a warehouse or between different locations. These movements can be classified into different types, each with its own purpose and characteristics.

The following table summarizes the different types of inventory movements:

| Type of Movement | Description | Example |

|---|---|---|

| Raw materials inward | The movement of raw materials into the warehouse from suppliers. | Purchase of raw materials from a supplier. |

| Work in progress outward | The movement of work in progress (WIP) from the production area to the finished goods warehouse. | Transfer of partially completed products from the production line to the finished goods warehouse. |

| Finished goods inward | The movement of finished goods into the warehouse from the production area. | Transfer of completed products from the production line to the finished goods warehouse. |

| Finished goods outward | The movement of finished goods out of the warehouse to customers. | Sale of finished goods to a customer. |

Impact of Inventory Movements on Business Operations

Inventory movements play a crucial role in various aspects of business operations, influencing key decisions and overall performance. Understanding the impact of inventory movements on production planning, sales forecasting, customer service, and financial performance is essential for businesses to optimize their operations and achieve their goals.

Production Planning

Inventory movements directly affect production planning. Accurate inventory data enables businesses to forecast demand, plan production schedules, and ensure they have the necessary raw materials and components on hand. Efficient inventory management minimizes production delays, reduces waste, and optimizes resource allocation.

Sales Forecasting

Inventory movements provide valuable insights for sales forecasting. By tracking inventory levels, businesses can better predict future sales trends. This information helps sales teams adjust their strategies, set realistic targets, and avoid overstocking or understocking situations.

Customer Service, Business central inventory movement

Inventory movements impact customer service by ensuring product availability and timely delivery. Adequate inventory levels enable businesses to fulfill customer orders promptly, enhancing customer satisfaction and loyalty. Conversely, stockouts can lead to lost sales, frustrated customers, and reputational damage.

Financial Performance

Inventory movements have a significant impact on financial performance. Holding excess inventory ties up cash flow and incurs storage costs. Conversely, maintaining optimal inventory levels reduces carrying costs and improves cash flow. Inventory movements also affect profit margins, as the cost of goods sold is directly influenced by inventory levels.

Ultimate Conclusion

In conclusion, business central inventory movement plays a pivotal role in optimizing supply chains and driving business success. By leveraging the best practices Artikeld in this guide, organizations can effectively manage inventory levels, minimize costs, and enhance customer satisfaction. As technology continues to reshape inventory management, staying abreast of emerging trends is essential for businesses to remain competitive and thrive in the ever-evolving landscape.