Small business inventory programs are the unsung heroes of successful operations, empowering businesses to optimize their stock levels, reduce costs, and enhance customer satisfaction. This comprehensive guide will delve into the world of inventory management, exploring proven strategies, cutting-edge technologies, and actionable insights to help you master the art of inventory control.

From implementing robust inventory management systems to leveraging data analytics for informed decision-making, we’ll cover every aspect of inventory management essential for small businesses. Get ready to unlock the potential of your inventory and drive your business towards growth and profitability.

Inventory Management Strategies for Small Businesses

Effective inventory management is crucial for small businesses to optimize operations, reduce costs, and enhance customer satisfaction. Small businesses commonly employ various inventory management techniques to streamline their processes.

Implementing an inventory management system offers numerous benefits, including improved accuracy, reduced waste, and enhanced efficiency. By tracking inventory levels, businesses can prevent overstocking and stockouts, optimize storage space, and make informed purchasing decisions.

Managing Inventory Levels, Small business inventory programs

Managing inventory levels is essential for maintaining optimal stock levels. Safety stock refers to the minimum inventory level that ensures uninterrupted operations during unexpected fluctuations in demand or supply. Reorder points indicate when inventory levels reach a point where it’s time to replenish stock to avoid stockouts.

- Safety Stock:Protects against unexpected demand spikes or supply chain disruptions.

- Reorder Points:Triggers replenishment orders when inventory falls below a predetermined level.

Inventory Optimization Techniques

Optimizing inventory levels is crucial for small businesses to minimize costs and enhance efficiency. This involves finding the right balance between holding enough inventory to meet customer demand while avoiding overstocking and associated costs.

One effective strategy is just-in-time (JIT) inventory management. JIT aims to reduce inventory levels by receiving goods only when they are needed for production or sale. This approach minimizes holding costs, reduces waste, and improves cash flow.

Role of Technology in Inventory Optimization

Technology plays a vital role in inventory optimization. Software solutions can automate inventory tracking, forecasting, and replenishment. Real-time data analytics provide insights into inventory performance, allowing businesses to identify trends and make informed decisions.

- Inventory management software can track stock levels, monitor demand patterns, and generate reports.

- Automated replenishment systems can trigger orders when inventory falls below a certain threshold.

- Data analytics can help businesses identify slow-moving items, optimize safety stock levels, and forecast future demand.

Inventory Tracking and Control

Inventory tracking and control are essential for small businesses to manage their inventory accurately and efficiently. Effective tracking and control measures help businesses minimize losses, optimize inventory levels, and ensure the availability of products when customers need them.

Methods for Tracking Inventory

There are several methods that small businesses can use to track their inventory accurately:

- Physical Counts:Conducting regular physical counts of inventory involves manually counting the number of items on hand. This method is simple and straightforward but can be time-consuming and prone to errors.

- Barcode Scanning:Using barcode scanners to track inventory allows businesses to automate the process of counting and recording inventory levels. Barcode scanners can quickly and accurately capture data from product barcodes, reducing the risk of errors and improving efficiency.

- RFID Technology:Radio frequency identification (RFID) technology uses radio waves to identify and track items. RFID tags can be attached to products, allowing businesses to track their movement and location in real-time. This technology provides a high level of accuracy and can be used to automate inventory tracking processes.

Importance of Inventory Control

Inventory control is crucial for small businesses to prevent theft, shrinkage, and other losses. Effective inventory control measures include:

- Establishing Clear Inventory Policies:Developing and implementing clear policies and procedures for inventory management helps ensure that all employees are aware of their responsibilities and follow consistent practices.

- Implementing Access Controls:Restricting access to inventory areas and implementing access controls, such as locks, security cameras, and employee badges, can help prevent unauthorized access and theft.

- Regular Audits:Conducting regular audits of inventory levels helps identify discrepancies and potential losses. Audits can be conducted by internal staff or external auditors to ensure accuracy and objectivity.

Inventory Tracking Software

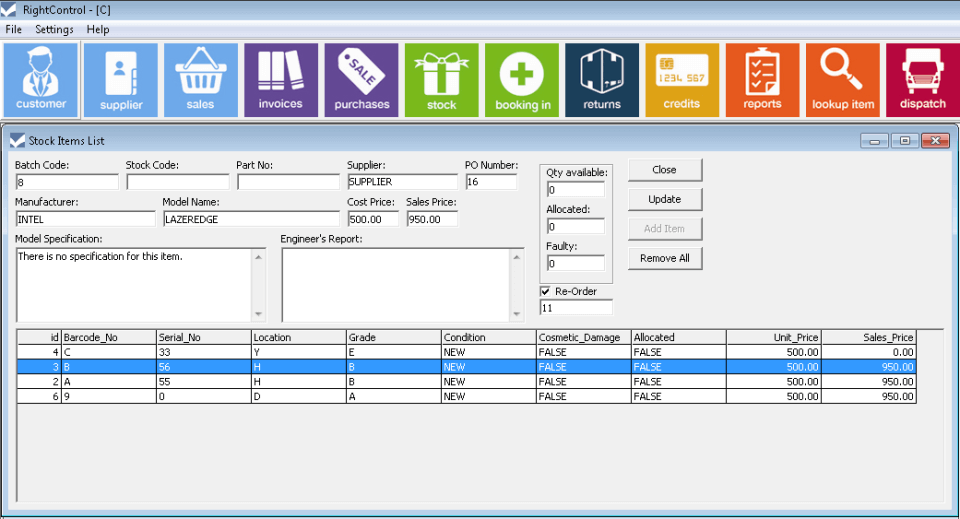

Inventory tracking software can streamline inventory management processes and provide businesses with real-time visibility into their inventory levels. These software solutions can automate inventory tracking, generate reports, and provide insights into inventory performance. Using inventory tracking software can help small businesses improve inventory accuracy, reduce costs, and optimize inventory levels.

Inventory Forecasting and Demand Planning

Inventory forecasting and demand planning are crucial for small businesses to optimize inventory levels and avoid stockouts or overstocking. By accurately predicting future demand, businesses can make informed decisions about inventory replenishment and production.

Inventory forecasting involves techniques such as historical data analysis and trend analysis to estimate future demand. Historical data provides insights into past demand patterns, while trend analysis identifies changes in demand over time. This information can be used to create demand forecasts, which are essential for inventory planning.

Demand Planning

Demand planning is the process of developing strategies to meet future demand. It involves analyzing market trends, customer behavior, and competitive factors to create a comprehensive demand plan. An effective demand plan Artikels the anticipated demand for each product or service, taking into account seasonal fluctuations, promotional activities, and other factors.

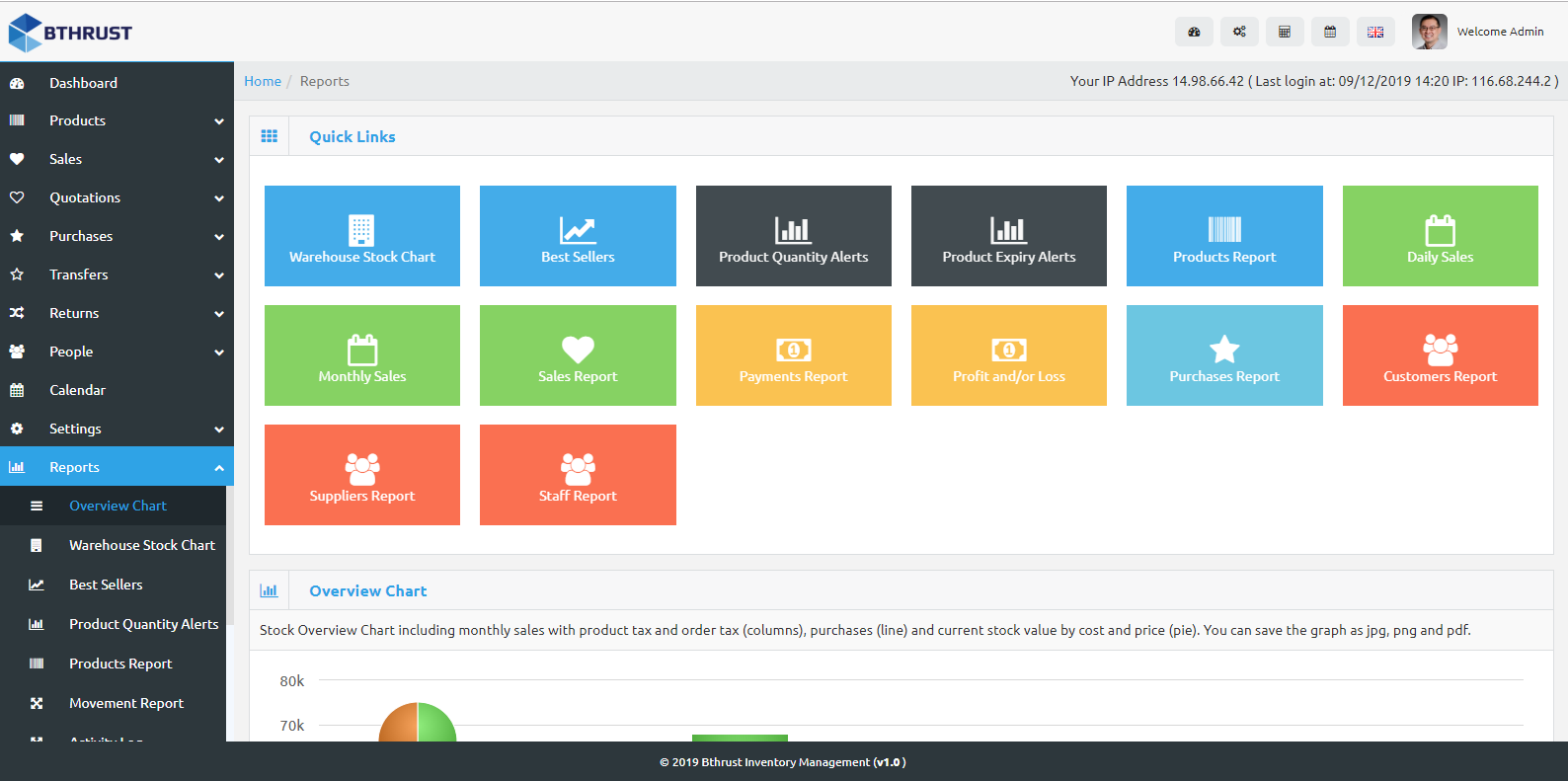

Inventory Forecasting Software

Several inventory forecasting software and tools are available to assist small businesses in demand forecasting. These tools use advanced algorithms and machine learning techniques to analyze historical data and generate accurate forecasts. Some popular options include:

- Zoho Inventory

- Fishbowl

- NetSuite

Inventory Reporting and Analysis

Inventory reporting and analysis are crucial for small businesses to monitor and manage their inventory effectively. By analyzing inventory data, businesses can gain insights into inventory turnover, stock levels, and trends, which can help them make informed decisions regarding inventory management.

Types of Inventory Reports

Small businesses should utilize various inventory reports to gain a comprehensive understanding of their inventory status. Key reports include:

- Inventory Turnover Reports:These reports measure how efficiently inventory is being sold and replaced. A high inventory turnover rate indicates efficient inventory management, while a low rate may suggest overstocking or slow-moving items.

- Stock Status Reports:These reports provide a snapshot of current inventory levels, including the quantity on hand, allocated, and available for sale. Stock status reports help businesses identify stock shortages or surpluses, enabling them to make timely adjustments to their inventory levels.

Data Analysis and Visualization

Analyzing inventory data is essential for identifying trends and patterns. By comparing historical data, businesses can spot seasonal fluctuations, demand changes, and other factors that influence inventory levels. Data visualization tools can be leveraged to present inventory data in a clear and concise manner, making it easier to understand and draw meaningful conclusions.For example, businesses can use charts and graphs to visualize inventory turnover rates over time, or create heat maps to identify slow-moving or fast-moving items.

By visually representing inventory data, businesses can quickly identify areas for improvement and make informed decisions about their inventory management strategies.

Inventory Management Software and Solutions

Inventory management software streamlines the tracking, organization, and control of inventory levels for small businesses. These systems offer various features and capabilities tailored to the unique needs of small businesses.

Types of Inventory Management Software

- Cloud-Based Systems:Hosted on remote servers, these systems provide real-time access from any device with an internet connection. They offer scalability, ease of use, and reduced IT infrastructure costs.

- On-Premise Systems:Installed on a local server within the business premises, these systems provide greater control over data and customization. However, they require significant upfront investment and ongoing maintenance.

- Mobile Apps:Designed for smartphones and tablets, these apps offer on-the-go inventory management, barcode scanning, and order processing. They are ideal for businesses with mobile workforces or those operating in multiple locations.

Features and Benefits

- Inventory Tracking:Real-time visibility into inventory levels, locations, and movements.

- Order Management:Streamlined order processing, fulfillment, and tracking.

- Reporting and Analytics:Comprehensive reports and dashboards for inventory performance analysis and decision-making.

- Barcode Scanning:Automated data entry and reduced errors in inventory management.

- Integration with Other Systems:Seamless integration with accounting, CRM, and e-commerce platforms.

Selecting the Right Software

Consider the following factors when selecting inventory management software for a small business:

- Business Size and Complexity:Choose software that aligns with the size and complexity of your inventory operations.

- Features and Functionality:Identify the specific features and functionality required for your business.

- Budget:Determine the budget for software purchase, implementation, and ongoing maintenance.

- Ease of Use:Select software that is user-friendly and requires minimal training for employees.

- Vendor Support:Ensure the vendor provides reliable technical support and customer service.

Conclusion

In conclusion, small business inventory programs are not merely tools for tracking stock; they are strategic assets that can transform your operations. By embracing the insights and strategies Artikeld in this guide, you can optimize your inventory levels, streamline processes, and gain a competitive edge in today’s dynamic market.

Remember, effective inventory management is the key to unlocking efficiency, profitability, and customer delight.

FAQ: Small Business Inventory Programs

What are the key benefits of implementing a small business inventory program?

Small business inventory programs offer numerous benefits, including reduced costs, improved efficiency, enhanced customer satisfaction, and better decision-making through data analytics.

How can I choose the right inventory management software for my small business?

Consider factors such as the size and complexity of your inventory, your budget, the features you need, and the level of support you require when selecting inventory management software.

What are some best practices for managing inventory levels?

Best practices include setting safety stock levels, establishing reorder points, and implementing inventory optimization techniques like just-in-time inventory management.